Armfield – Chemical Engineering – CEXC Computer Controlled Chemical Reactors Training Equipment

The Armfield CEXC family is a range of chemical reactors specifically developed for the teaching and demonstration of chemical reactor capabilities to chemical engineering students. Real chemical reactions take place within the reactors, and Armfield have developed a number of representative reactions which are easy and safe for students to use in the laboratory environment. This range of small-scale chemical reactors comprises five units, which represent the types of reactors found in the industry. Three of the reactors mount on a common bench top service unit (CEXC) whilst the other two are free-standing. PC based educational software is included along with the necessary interface device to provide computer control, automatic logging of data and analysis of results. Reactors comprise: Plug Flow, Laminar Flow, Stirred Tank, Tubular and Batch reactors.

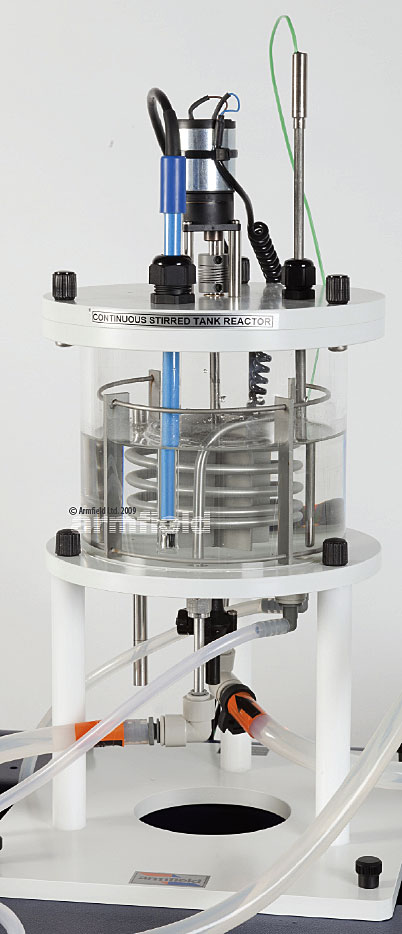

The CEXC Chemical Reactors Teaching Unit provides the services required to run the various reactor types. It includes a hot water re-circulator used to control the temperature of the reactions, glass feed vessels for the reactants, two peristaltic pumps to pump the reagents to the reactors, computer software for data logging, sensors and instrumentation.

The CEXC is fully computer controlled, and supplied with software to allow the user to vary the feed pump speeds and flow rates, to vary the heater power in the hot water, to implement a PID control loop ensuring stable temperatures, switch on and off the hot water pump, and to control the speed of the stirrers used on some of the reactors.

Instrumentation for temperature and conductivity measurements is also supplied and these values are displayed on the computer screen. Two ‘K’ type thermocouples are included, one for the hot water and one for the reactor contents.

Note: An input for a third user supplied sensor is also provided for project work.

A dual-range conductivity sensor allows for a wide range of operation. Armfield have developed an algorithm for the saponification reaction (ethyl acetate and sodium hydroxide) linking the degree of conversion of the reactants to the electrical conductivity, thus allowing the progress of the reaction to be monitored using the software.

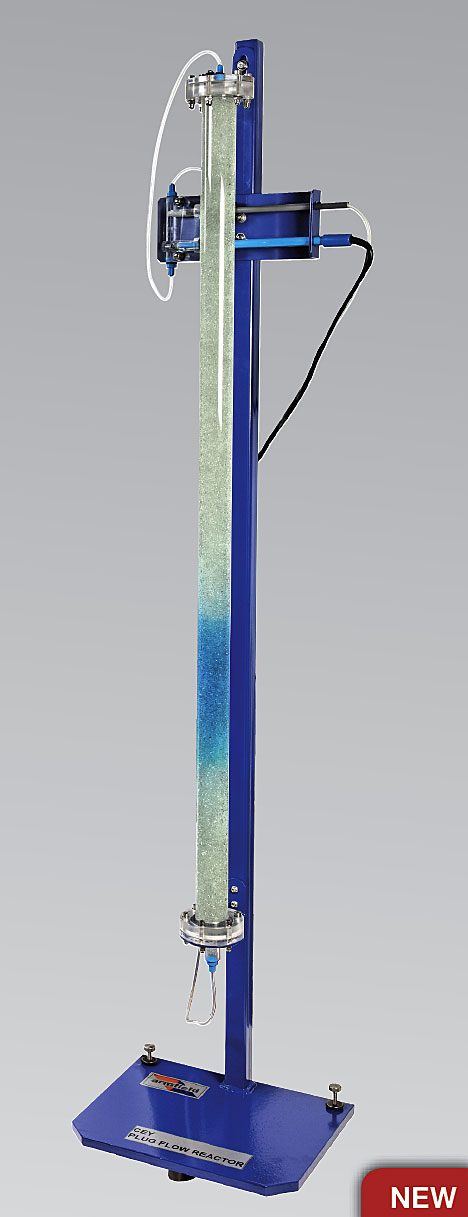

The service unit includes a mounting position for the reactor being used. It is possible to change reactors quickly and easily without the use of tools. All fittings on the CEXC and the reactors are of the quick-release type. The CEM-MkII, CET-MkII and CEB-MkIII reactors are completely contained on the CEXC base unit. The CEY and CEZ also include floor standing columns for positioning next to the CEXC base unit.

The CEXC provides a locating position for two standard 2.5-litre chemical storage bottles for the reagents within the plinth. This provides safety in use, and the bottles can be quickly capped and removed as necessary for safe handling. Two 2.5-litre bottles are also provided with the equipment. Alternatively, for longer experiments, larger feed vessels could be located either on the floor or on the bench next to the equipment.

The CEXC requires a computer (not supplied by Armfield), running Windows XP or above, with a spare USB port.

Available Models

Key Features

CEXC Computer Controlled Chemical Reactors Training Equipment

- A self-contained benchtop service unit designed to provide services for up to five different chemical reactors:

- Continuous Stirred Tank Reactor

- Tubular Reactor

- Transparent Batch Reactor

- Plug flow reactor

- Laminar Flow reactor

- Fully computer controlled and supplied with educational software specific to each reactor type. Simple interfacing to the (user-supplied) computer by a USB interface

- Two peristaltic feed pumps with individually variable flow rates, 0-140 ml/min

- Provides PID temperature controlled hot water in order to maintain reactor temperature

- Complete with two thermocouples, an input for a third (user) thermocouple and a dual range conductivity sensor

- A comprehensive instruction manual is included, which details installation and operating procedures

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Oil & Gas

- Pharmaceutical

- Powders & Pigments / Coating

Brand

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and pharmaceutical industries. Used by many of the world’s leading corporations, Armfield systems enable researchers and product developers to replicate full-scale industrial manufacturing processes on a miniature-scale in the laboratory.

Similar Products