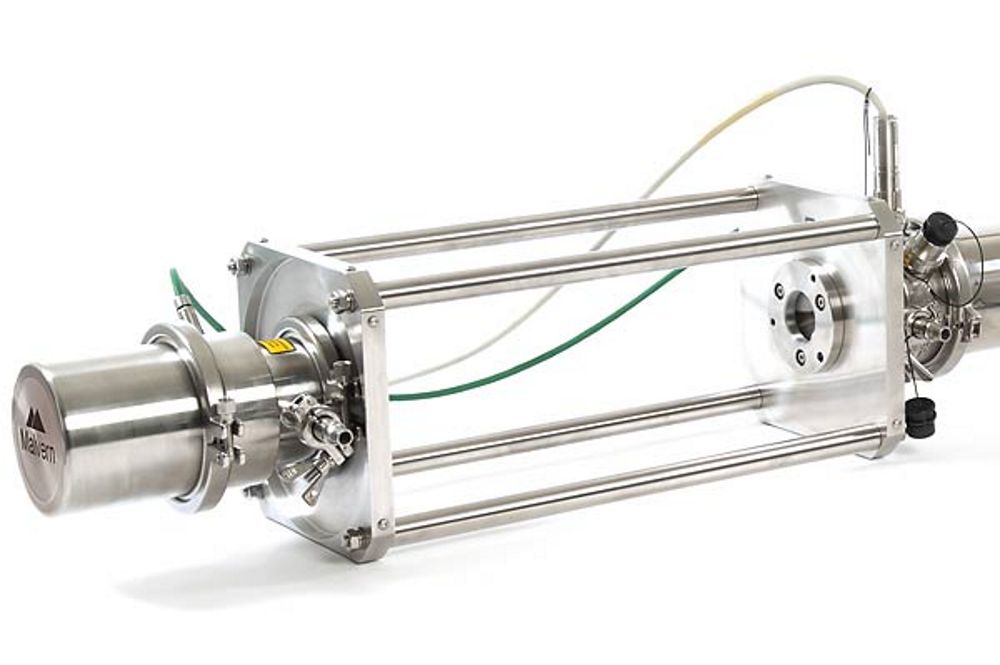

Malvern Panalytical – Particle Characterization – Insitec Range

Robust, Reliable, Real-Time Particle Sizing

Malvern Insitec systems deliver the online continuous particle size analysis needed for efficient, cost-effective monitoring and control of industrial processes. Suitable for the widest variety of process streams from dry powders to hot sticky slurries, sprays and emulsions, whether milligrams of material or hundreds of tonnes per hour. Insitec systems measure particles in the size range 0.1 micron to 2.5 mm.

For applications about Malvern Insitec range, click here

DKSH is the exclusive distributor in Cambodia, Indonesia, Laos, Malaysia, Myanmar, Philippines, Singapore, Taiwan, Thailand and Vietnam.

Technical Specifications

| Measurement type | Particle size |

| Measurement range | 0.1 to 2500 µm |

|---|---|

| Measurement principle | Laser diffraction |

| Optical model | Mie theory |

| Accuracy | ±2% on Dv(50) |

| Power | 100 / 240 V |

| Enclosure rating | IP65 |

| Operating platforms | 10 bar (g) |

| Operating temperature | 10°C to 70°C |

| Operating Humidity | 35% to 80% |

Available Models

Key Features

- Base model hardware manufactured to GAMP5 standards and compatible with CIP/SIP requirements to meet specific manufacturing specifications

- Easy to use software and fully automated operation to minimize training requirements and release operator time

- Integration with existing control platforms to simplify development of automated control protocols

- High reliability of >95% with little downtime, minimal maintenance and maximum ROI

Insitec: on-line Particle Size Analysis for Automated Milling Control

This video shows how Malvern Instruments Insitec particle size analyzer is used to control and automate a milling process. Real-time measurement of particle size distribution (PSD) is used as a feedback for controlling raw material feed rate.

Key Industries

- Automotive

- Biopharmaceutical and Biotechnology

- Chemical

- Environmental

- Machinery & Manufacturing

- Mining & Minerals

- Pharmaceutical

Brand

Malvern Panalytical was formed by the merger of Malvern Instruments Limited and PANalytical B.V. on 1st January 2017, has headquarters in both Almelo (the Netherlands), and in Malvern (UK), and employs over 2,000 people worldwide. The combined entity is a strong player and innovator in the materials characterization market and will leverage the strengths of the individual companies in their end markets, ranging from building materials to pharmaceuticals and from metals and mining to nanomaterials.

Similar Products