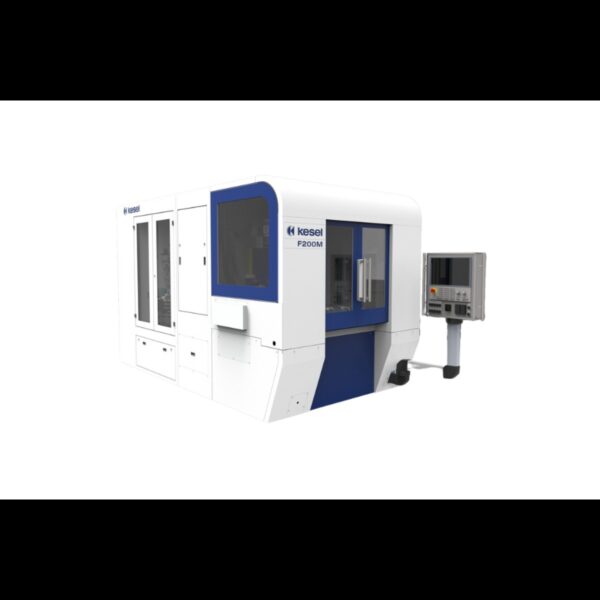

Georg Kesel – Band Straightening Machine – BR 100s

Improve quality, speed up manufacturing and add additional value to your saw products with the BR 100s automatic straightening machine. Designed for ease of operation, the BR 100s is a ‘Plug and Play’ machine that will eithe...

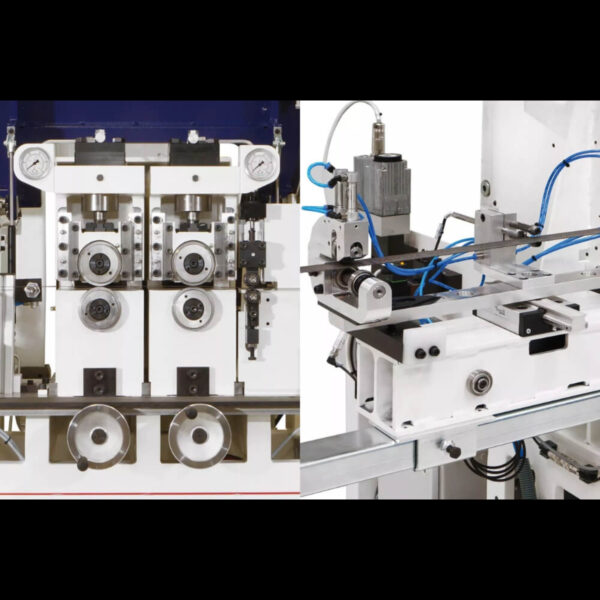

Improve quality, speed up manufacturing and add additional value to your saw products with the BR 100s automatic straightening machine. Designed for ease of operation, the BR 100s is a ‘Plug and Play’ machine that will either straighten-out unwanted camber or create a defined camber at the touch of a button.

With its intelligent ‘teach-in’ operating system the BR 100s automatically learns the optimal parameters required to process each band material and camber and will self-adjust to maintain perfect results. This gives your machine operators freedom to complete other tasks and also means that unparalleled production volumes can be reached.

With optional titling pay-out and take-up units and integrated slack monitoring, material handling and transportation is seamless. And with the ability to export a digital straightening protocol the BR 100s can also form a valuable part of your QC management system.