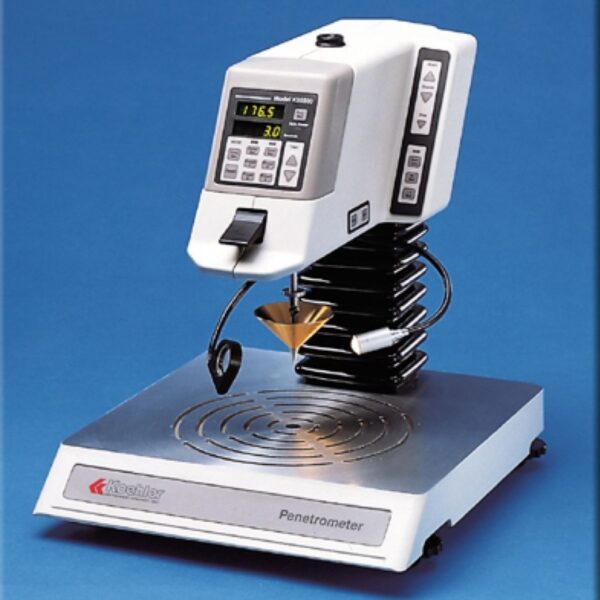

Koehler – Penetrometer – Digital Penetrometer

Penetration tests are performed on petroleum products to determine consistency and shear stability (lubricating greases) for design, quality control and identification purposes. A standard cone or needle is released from a penetrometer and allowed...

Penetration tests are performed on petroleum products to determine consistency and shear stability (lubricating greases) for design, quality control and identification purposes. A standard cone or needle is released from a penetrometer and allowed to drop freely into the sample for 5 seconds (or a different specified interval) at constant temperature. The depth of penetration of the cone or needle into the sample is measured in tenths of a millimeter by the penetrometer.