most versatile freeform generator

This latest generation of our true flag ship machine has been proven worldwide to be the most flexible, precise, and user friendly ultra precision freeform diamond turning system available....

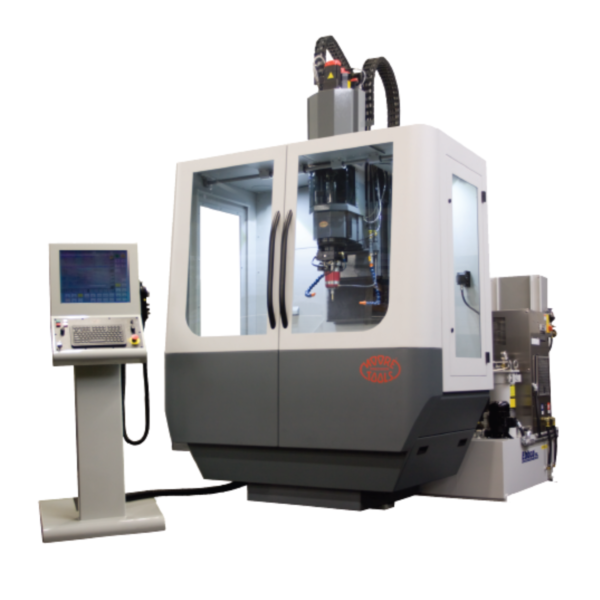

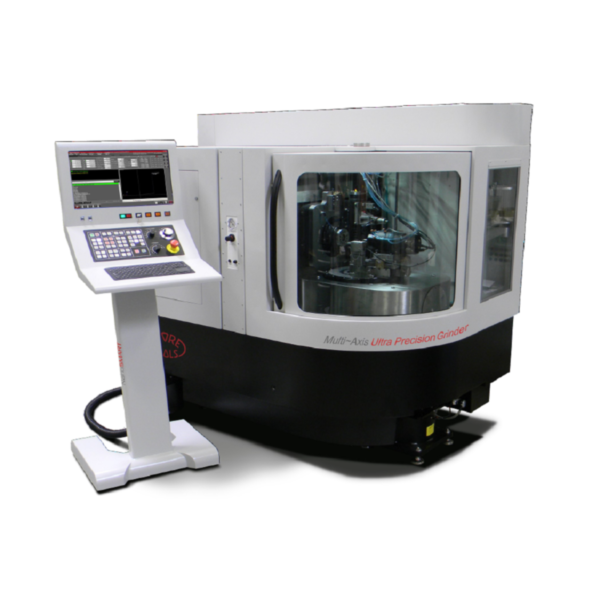

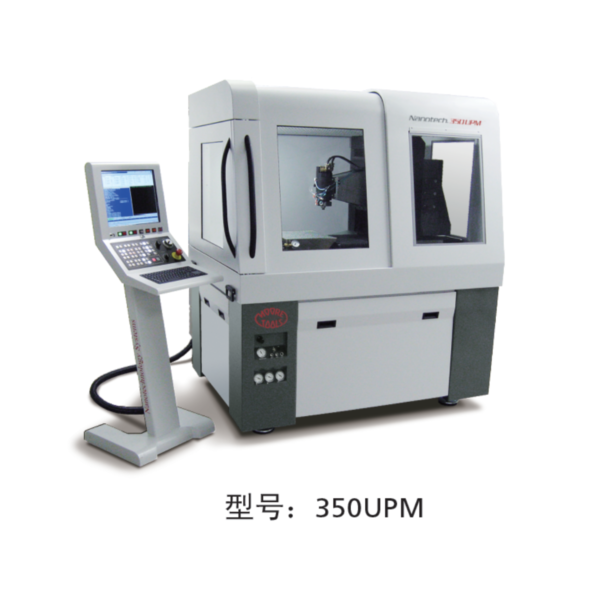

most versatile freeform generator

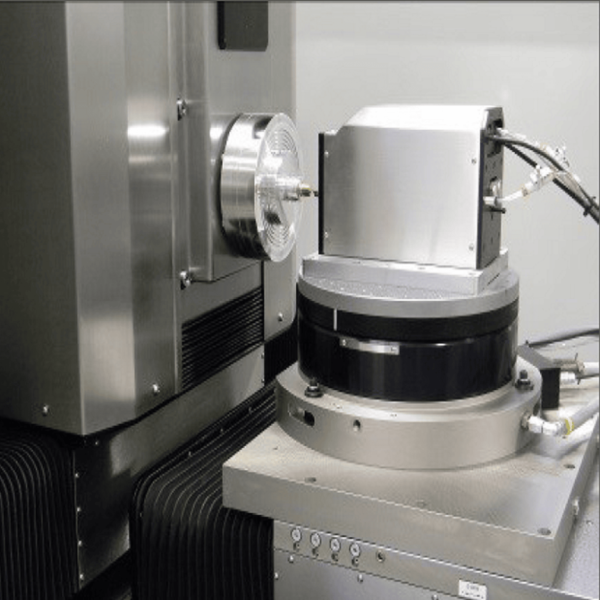

This latest generation of our true flag ship machine has been proven worldwide to be the most flexible, precise, and user friendly ultra precision freeform diamond turning system available. With a minimum of three precision linear X, Y, and Z axes, the 650FGv2 is expandable to a five-axis system via optional B & C rotary axes. With the main work spindle centrally integrated within an oil hydrostatic Y-axis carriage, advanced machining methods such as raster flycutting of linear diffractives and freeforms, micro-prismatic optical structures, micro-milling of aspheric lens arrays as well as Slow Slide Servo (S3) machining of toric, biconic surfaces are achievable.

NanoSMART® Windows Based Interactive HMI Control System

A high speed 64 bit Delta Tau PowerPMAC Motion Controller with the Nanotech’s own touch / swipe gesture HMI, NanoSMART. Three customizable 22″ wide screens are accessible by swiping left or right from the main screen. Ability to handle 5GB program file sizes, 4X faster processing speeds, remote diagnostics and a leading 8 picometer feedback resolution combine to make the new Nanotech 650FGv2 the most user friendly high performance multi-axis diamond turning system available. We welcome you to experience the difference for yourself!