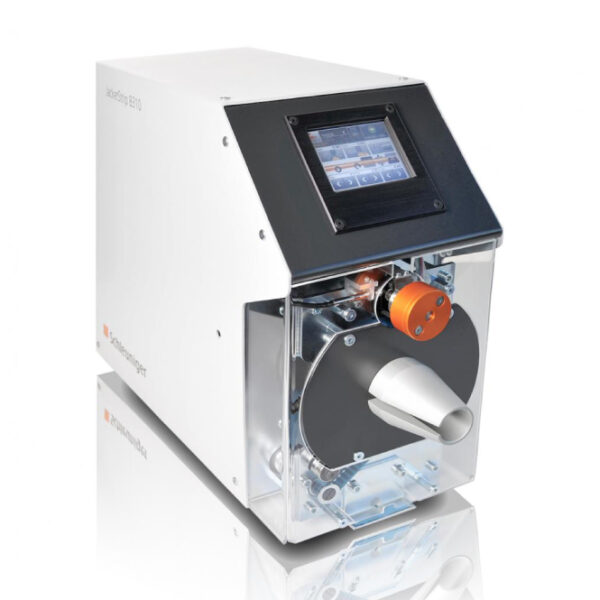

Schleuniger – Pull Force Testing

It’s a motorized pull force test devices for forces from 100 N (22.5 lbf) up to 10,000 N (2,250 lbf). Capabilities such as multiple force ranges and pulling rates, job memory and networking capabilities vary between models. Wire and terminal...

It’s a motorized pull force test devices for forces from 100 N (22.5 lbf) up to 10,000 N (2,250 lbf). Capabilities such as multiple force ranges and pulling rates, job memory and networking capabilities vary between models. Wire and terminal holders can be configured or customized to suit specific application