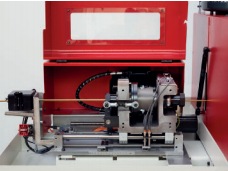

Escomatic – CNC – D2/D5 Flex Speed

Escomatic D2 Flex Speed, the fastest solution for precise and economic tuning up to 5.0 mm maximum diameter parts produced in large and medium lot sizes. Escomatic D5 Flex Speed, the D2 basic machine equipped in addition with a three stations end ...

Escomatic D2 Flex Speed, the fastest solution for precise and economic tuning up to 5.0 mm maximum diameter parts produced in large and medium lot sizes. Escomatic D5 Flex Speed, the D2 basic machine equipped in addition with a three stations end working unit with two spindles for drilling operations.

The ESCO FLEX SPEED system allows machining to be optimised while guaranteeing an extremely high level of productivity. This increases the performance advantages of cam driven machines. Thanks to the electronic control system, the speed of the cam shaft can be programmed for specific areas. For example, the feed rate can be reduced for parting and increased for turning; this means that the slowest process no longer determines the overall cycle time. In addition the spindle speeds and the straightening speeds can be continuously adjusted (no more changing of pulleys). Due to FLEX SPEED the parameter of each operation can be optimised individually, resulting in a significant improvement in the quality of the parts produced.