Solarius – Atlas

The new Polaris Desktop 3D surface measuring system from Solarius enables highly accurate and precise 3D imaging of surfaces. While th...

The new Polaris Desktop 3D surface measuring system from Solarius enables highly accurate and precise 3D imaging of surfaces. While the Polaris and the Polaris Plus are equal in accuracy and precision, the Polaris offers a cost effective variant for many applications. The Polaris Plus expands the scope of application due to its extensive equipment, which supports in particular simple automation of the measurement tasks.

Key Features

- Highest optical and digital resolution

- Diffraction limited imaging

- Reliable technology

- ISO compliant roughness values

- Non-contact measurements

- Maintenance-free and robust

Sensor Types

- Confocal area sensors

- Interferometric area sensors

The Solarius Polaris 3D measuring system is based on the spinning disc confocal technique, proven over many years. In the design and calculation of the optics, great importance was attached to a physically optimal diffraction limitation ofthe optical system, which allows for accurate, precise and repeatable lateral measurements even in structural areas far below one micrometer.

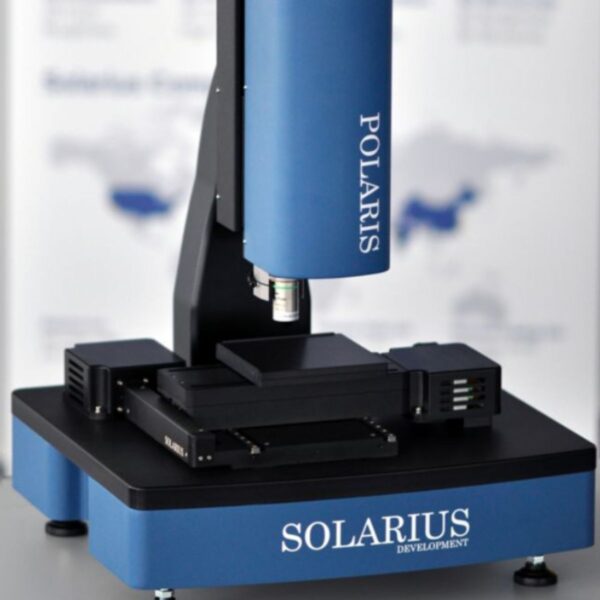

Solarius – Polaris

The new Polaris Desktop 3D surface measuring system from Solarius enables highly accurate and precise 3D imaging of surfaces. While the Polaris and the Polaris Plus are equal in accuracy and precision, the Polaris offers a cost ...

The new Polaris Desktop 3D surface measuring system from Solarius enables highly accurate and precise 3D imaging of surfaces. While the Polaris and the Polaris Plus are equal in accuracy and precision, the Polaris offers a cost effective variant for many applications. The Polaris Plus expands the scope of application due to its extensive equipment, which supports in particular simple automation of the measurement tasks.

Key Features

- Highest optical and digital resolution

- Diffraction limited imaging

- Reliable technology

- ISO compliant roughness values

- Non-contact measurements

- Maintenance-free and robust

Sensor Types

- Confocal area sensors

- Interferometric area sensors

The Solarius Polaris 3D measuring system is based on the spinning disc confocal technique, proven over many years. In the design and calculation of the optics, great importance was attached to a physically optimal diffraction limitation ofthe optical system, which allows for accurate, precise and repeatable lateral measurements even in structural areas far below one micrometer.

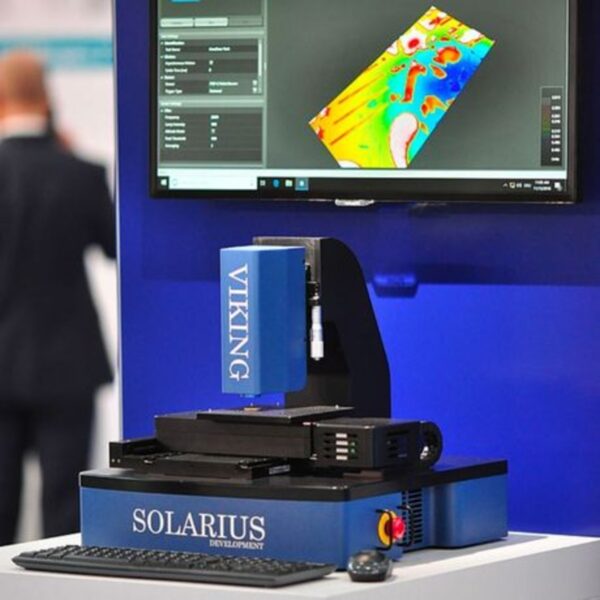

Solarius – Viking

The Viking is an optical non-contact profilometer for affordable 3D surface and roughness measurements. Its small footprint and light weight design makes it ideal as a desktop 3D measurement tool. It is designed to meet mid-rang...

The Viking is an optical non-contact profilometer for affordable 3D surface and roughness measurements. Its small footprint and light weight design makes it ideal as a desktop 3D measurement tool. It is designed to meet mid-range accuracy and quality control needs using state-of-the-art sensor technology to generate 3D surface topography maps and ISO compliant roughness information.

Key Features

- Short learning curve and fast setup

- Non-destructive 3D quality assurance

- Automated 3D surface metrology

- Measurement report generator

- Fast replacement for tactile systems

- ISO compliant surface roughness measurements

Sensor Types

- Chromatic confocal point sensors

- Point triangulation sensors

- Line triangulation sensors

Viking’s productivity benefits lie in its easy to learn user interface allowing to quickly set up 3D optical inspection procedures. New operators spend less time learning to use the system and more time making measurements with it.

Surfx – Argon Plasma Systems

The AtomfloTM 600 argon plasma system is ideally suited for in-line cleaning and activation of materials prior to bonding. The plasma produces a beam of reactive atoms that etch away contaminants on the surface all the way down to the...

The AtomfloTM 600 argon plasma system is ideally suited for in-line cleaning and activation of materials prior to bonding. The plasma produces a beam of reactive atoms that etch away contaminants on the surface all the way down to the atomic scale. The compact and lightweight plasma head, together with the low-voltage, radio-frequency power supply, make it safe and easy to integrate surface treatment into any assembly line. The beam of reactive atoms is low temperature and 100% electrically neutral. It treats metals, glass, and plastics. It will not damage sensitive electronics, or thin film polymers, such as polyethylene. An in-line production system can treat millions of parts per year at a cost of ownership of a few cents per part.

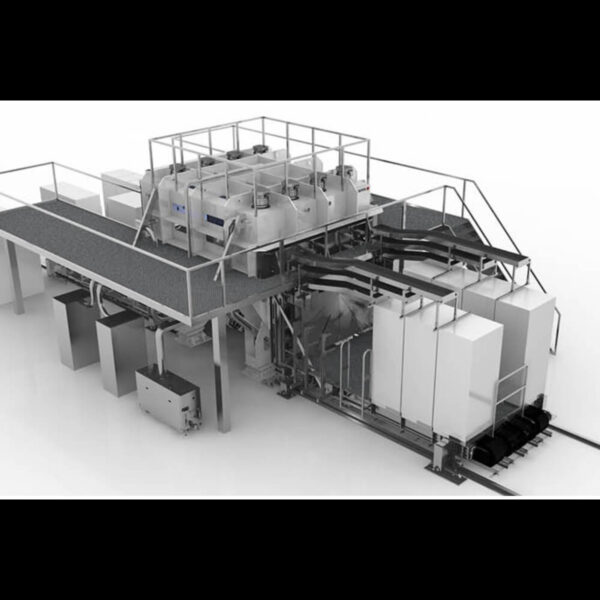

Surfx – Automation and Integration

Surfx provides turnkey and OEM plasma systems for surface treatment of just about any part, regardless of size, shape, or production quantity. We proudly supply the most trusted atmospheric plasma machines to industries all ov...

Surfx provides turnkey and OEM plasma systems for surface treatment of just about any part, regardless of size, shape, or production quantity. We proudly supply the most trusted atmospheric plasma machines to industries all over the world. Trust has been built by a relentless pursuit of process tools that are unsurpassed in versatility, speed, selectivity, reliability and cost effectiveness. Surfx promises to deliver a level of automation and integration that is optimally configured for the customer’s needs, whether it be for mass production, high product mix, or research and development.

Key Features

- Gain flexibility and agility

- Eliminate excuses

- Entry level solution

- Eliminate the wait

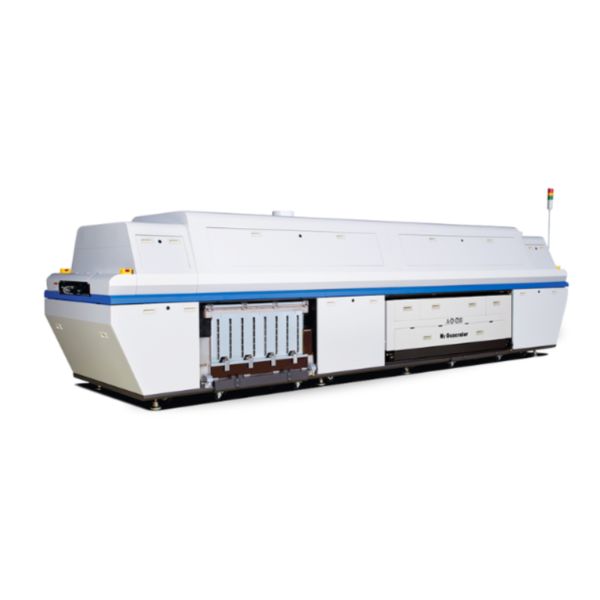

TSM – Air Reflow

The TRA series is the outcome of realizing Econology and offers the best performance. Satisfying the economic effectiveness and practicality of your business.

The TRA series is the outcome of realizing Econology and offers the best performance. Satisfying the economic effectiveness and practicality of your business.

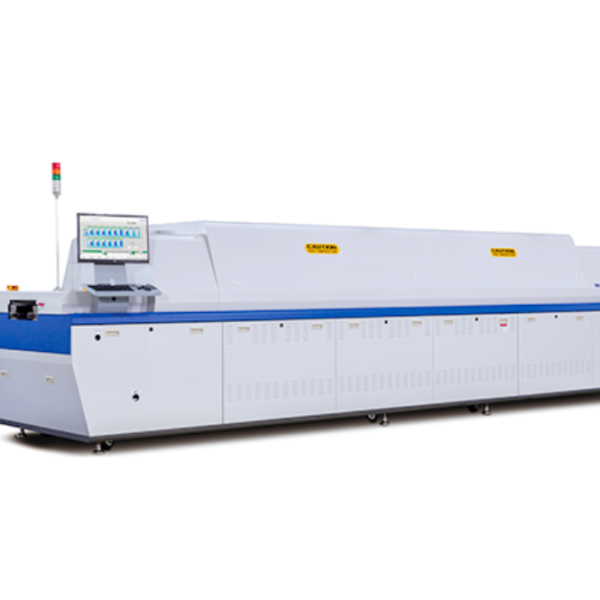

TSM – N2 Reflow (TRN III-a)

The TSM N2 Reflow is a high-end reflow oven that provides precise temperature control for the most demanding soldering applications. It features a nitrogen atmosphere that minimizes oxidation and improves soldering quality, ensuring consistent and...

The TSM N2 Reflow is a high-end reflow oven that provides precise temperature control for the most demanding soldering applications. It features a nitrogen atmosphere that minimizes oxidation and improves soldering quality, ensuring consistent and reliable results. With a compact design and intuitive user interface, the TSM N2 Reflow is a must-have for any electronics manufacturing facility looking to achieve the highest levels of quality and efficiency.

Key Features

- Realize Flux Zero in OVEN -> equip FMS applied with patent technology

- Thermal Interference Innovation in each zone -> Able to set up temperature difference with 60ºC in max. of interzone

- Internal Heat Reduction of Reflow -> apply New Emission System

- Real-time Monitoring,temperature Profile Monitoring and Oxygen Concentration Monitoring in each zone

- Conveyor Vibration Monitoring

TSM – Vacuum Reflow

The TRV series offers the outstanding productivity and safety operation of equipment. Particularly , the Compact Vacuum Chamber and Conveyor are technically proved solutions in the field through a technical partnership with ETC....

The TRV series offers the outstanding productivity and safety operation of equipment. Particularly , the Compact Vacuum Chamber and Conveyor are technically proved solutions in the field through a technical partnership with ETC.

Key Features

- Completely sealable TSM’s vacuum Reflow, dedicated compression chamber

- Transfer System without jamming PCB (technical partnership with ETC)

- Prevent PCB Drop by minimizing the gab between in/outlet entrance of conveyor in vacuum chamber

- Strengthen durability without conveyor driven roller in high temperature section

- Able to correspond with minimized vacuum chamber with embedded vacuum pump

- Reduce time of vacuuming and easily control vacuum

Viscom – Solder Paste Inspection – iS6052-SPI

The iS6052 SPI is Viscom’s...

The iS6052 SPI is Viscom’s cutting-edge solution for precise solder paste inspection in SMD production. With over four decades of expertise behind it, this 3D inline system ensures comprehensive evaluation of key solder features such as volume, height, shape, and more. Advanced sensor technology, including an orthogonal camera and four lateral views, enhances inspection accuracy, while realistic color imaging accelerates verification. The Fast Flow handling system boosts throughput, synchronizing assembly flow seamlessly and minimizing handling times. Equipped with intelligent networking capabilities, the iS6052 SPI offers superior process stability and efficiency for modern SMT lines.

Viscom_Bond Inspection_X7056-II BO

The inspection system X7056-II BO effectively combines optical in-line wire bond control with automatic X-ray inspections. This

The inspection system X7056-II BO effectively combines optical in-line wire bond control with automatic X-ray inspections. This comprehensive inspection concept enables higher efficiency, optimizes cycle times and thus improves throughput. Where the bottom line is concerned, procurement costs are significantly lower than purchasing two separate inspection systems. The Viscom inspection software is designed for maximum inspection depth and accuracy. The standard library contains inspection patterns for die, ball-wedge, wedge-wedge and security bonds. The inspection scope can be individually extended. During the inspection, high-resolution optical camera technology captures all bond sites and wires. The automatic X-ray inspection then follows seamlessly. Thus, for example, hidden connection sites can also be reliably inspected in one run.

Viscom_Optical Inspection_iS6052 THT

The iS6052 THT inspection system is the most efficient quality control inspection of Viscom. Engineered for precise component placement verification on THT (Through-Hole Technology) boards. Utilizing advanced AOI (Automated Optical Inspection) tec...

The iS6052 THT inspection system is the most efficient quality control inspection of Viscom. Engineered for precise component placement verification on THT (Through-Hole Technology) boards. Utilizing advanced AOI (Automated Optical Inspection) technology, it inspects from above the PCB, setting it apart from conventional systems that inspect from below. Designed for accuracy and efficiency, the iS6052 THT ensures reliable quality assurance in THT assembly processes.

Viscom- X-ray Inspection- iX7059-one

The iX7059 One can guarantee exceptional precision, with a resolution down to 1µm, ensuring every detail is captured with accuracy. This advanced system offers versatile 2D, 2.5D, and 3D X-ray inspection capabilities, m...

The iX7059 One can guarantee exceptional precision, with a resolution down to 1µm, ensuring every detail is captured with accuracy. This advanced system offers versatile 2D, 2.5D, and 3D X-ray inspection capabilities, making it perfect for semiconductor, power module, and leadframe applications. Designed for 100% inline inspection, the iX7059 One excels in detection, providing reliable performance for high-volume production. With easy programming and seamless integration, it’s the ideal solution for manufacturers seeking consistent quality and efficiency.

VJ Electronix – Apogee 90

The APOGEE 90 was built to fulfill the need for an affordable and reliable inspection system with advanced features for defect detection, failure analysis, and NDT in production environments. The system is capable of capturing t...

The APOGEE 90 was built to fulfill the need for an affordable and reliable inspection system with advanced features for defect detection, failure analysis, and NDT in production environments. The system is capable of capturing the highest clarity 2D & 2.5D x-ray images that provide operators with confidence in their findings.

VJ Electronix – Summit 1800i

The most installed rework system in the world. The Summit 1800i is capable of handling boards up to 22″x30” and components as small as 01005. Built with easy-to-use 1-2-3-GO software, operation of this rework system is s...

The most installed rework system in the world. The Summit 1800i is capable of handling boards up to 22″x30” and components as small as 01005. Built with easy-to-use 1-2-3-GO software, operation of this rework system is simple and intuitive. Efficient convection heating provides high thermal throughput, uniformity, and a repeatable rework process. Proprietary software provides product traceability, profile analysis, and sharing of profiles between VJE systems.

VJ Electronix – Summit 2200i

Our rework system boasts user-friendly 1-2-3-GO software and efficient convection heating, along with proprietary software for product traceability and profile sharing between VJE systems. Automated features enable the reworking...

Our rework system boasts user-friendly 1-2-3-GO software and efficient convection heating, along with proprietary software for product traceability and profile sharing between VJE systems. Automated features enable the reworking of large components, while non-contact site scavenging ensures the safe removal of residual solder. This system provides a reliable and efficient solution for rework processes.

Rework done on the Summit 2200i with Auto Align results in reliable, repeatable processes with greater system up-time, machine utilization, and a faster ROI.

VJ Electronix – Summit 750i

The cost-effective and high performance solution to your rework needs. The Summit 750i is capable of handling boards up to 18″x22” and components as small as 0201. Built with easy-to-use 1-2-3-GO software, operation of t...

The cost-effective and high performance solution to your rework needs. The Summit 750i is capable of handling boards up to 18″x22” and components as small as 0201. Built with easy-to-use 1-2-3-GO software, operation of this rework system is simple and intuitive. Efficient convection heating provides high thermal throughput, uniformity, and a repeatable rework process. Proprietary software provides product traceability, profile analysis, and sharing of profiles between VJE systems.

VJ Electronix – Summit Lxi

The go-to rework system for 5G, and large board applications. The Summit LXi is capable of handling boar...

The go-to rework system for 5G, and large board applications. The Summit LXi is capable of handling boards up to 25″x47” and components as small as 01005. Built with easy-to-use 1-2-3-GO software, operation of this rework system is simple and intuitive. Efficient convection heating provides high thermal throughput, uniformity, and a repeatable rework process. Proprietary software provides product traceability, profile analysis, and sharing of profiles between VJE systems.

VJ Electronix – XQuik II Plus

The XQuik II Plus is an improved version of the most installed component counter in the world today. With improved speed, higher count accuracy, and reduced cost, the XQuik II Plus is the go-to solution for your organization.

The XQuik II Plus is an improved version of the most installed component counter in the world today. With improved speed, higher count accuracy, and reduced cost, the XQuik II Plus is the go-to solution for your organization.

VJ Electronix – XQuik II Plus Autoload

The system’s advanced detection algorithms automatically recognize components without the need for cumbersome models, libraries, or cloud connection, making it quick and simple to use. Unique imaging technology provides the gr...

The system’s advanced detection algorithms automatically recognize components without the need for cumbersome models, libraries, or cloud connection, making it quick and simple to use. Unique imaging technology provides the greatest count accuracy and reliability.

The XQuik’s flexible MES interface is easily configured to communicate with any inventory control system. Automatic detection determines whether a single, or up to four small reels are loaded, and keeps track of reel location, eliminating the risk of operator error.

VJ Electronix – XQuik III

XQuik III Highest count accuracy in the simplest, fastest x-ray component counter. XQuik III counts the most difficult reels at the 99.8% industry accuracy standard.

XQuik III Highest count accuracy in the simplest, fastest x-ray component counter. XQuik III counts the most difficult reels at the 99.8% industry accuracy standard.

Von Ardenne – PIA l nova

The PIA | nova® is a modular, highly automated coating platform for depositing metallic contact coatings, transparent conductive oxides (TCO) and various absorber coatings such as for CIGS or CdTe technology. The modul...

The PIA | nova® is a modular, highly automated coating platform for depositing metallic contact coatings, transparent conductive oxides (TCO) and various absorber coatings such as for CIGS or CdTe technology. The modular concept allows the combination of high reliability and efficiency with the unique flexibility of configuring the coater according to the requirements of the customer.

Von Ardenne – Roll to Roll Web Coating

VON ARDENNE provides tailored web coating solutions for today’s most ambitious thin-film applications on polymer films, flexible glass and metal strip. These solutions comprise coating equipment, key technology components ...

VON ARDENNE provides tailored web coating solutions for today’s most ambitious thin-film applications on polymer films, flexible glass and metal strip. These solutions comprise coating equipment, key technology components and application technology. Our customers benefit from our extensive process know-how and our experience, which we have gained for more than 20 years in roll-to-roll coating, 45 years in magnetron sputtering and 60 years in electron beam technology.

Von Ardenne – XEA l nova

VON ARDENNE is the partner of choice, if you are looking for coating solutions for all current and future technologies for high-efficiency solar cells such as the heterojunction cell technology (HJT). Considerably improved contact structures compared to today’s standards are an essential feature of these cells. Another crucial aspect is the right key technology for depositing these structures on silicon wafers: Physical vapor deposition (PVD), a technology VON ARDENNE has perfected for more than 60 years. However, the potential of PVD is far from exhausted.

Youibot – Lifting Series – L1000

With a payload of 1000 kg, the L1000 is one of the most powerful autonomous mobile robots (AMRs). Designed to handle the heaviest workload in various facilities, as well as optimize intralogistics efficiency and throughput in wa...

With a payload of 1000 kg, the L1000 is one of the most powerful autonomous mobile robots (AMRs). Designed to handle the heaviest workload in various facilities, as well as optimize intralogistics efficiency and throughput in warehouses, it automates the movement of goods, racks, and pallets.

The YOUIFLEET management system enables fleet collaboration across up to 1000 AMRs under one system, enabling a true ‘light-out’ operation.

Youibot – Lifting Series – L300

L300 is the agile, perfect option for warehouses or manufacturing facilities with narrow passageways. Carrying a maximum payload of 300 kg, the AMR is equipped with a top module that elevates at a maximum height of 60mm and rota...

L300 is the agile, perfect option for warehouses or manufacturing facilities with narrow passageways. Carrying a maximum payload of 300 kg, the AMR is equipped with a top module that elevates at a maximum height of 60mm and rotates at 360 degrees. The YOUIFLEET dispatching system allows a fleet collaboration of up to 1,000 AMRs under the same operation area, enabling a real light-out operation.

test block for Laos

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Your download – just a few steps away

Please enter your details here:

test

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us