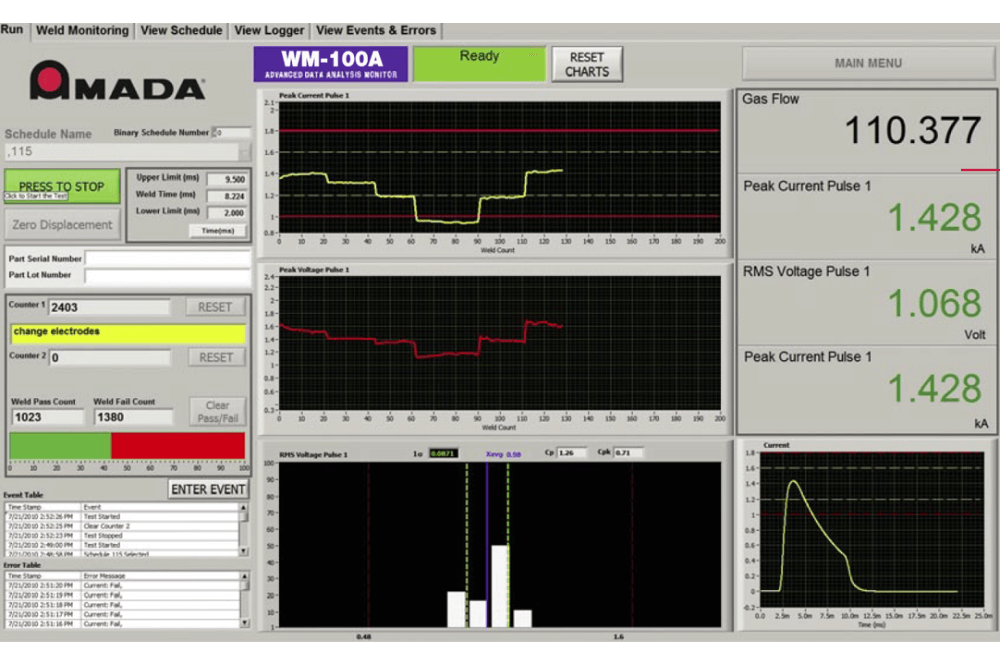

AMADA – Advanced Data Analysis Monitor – WM-100A

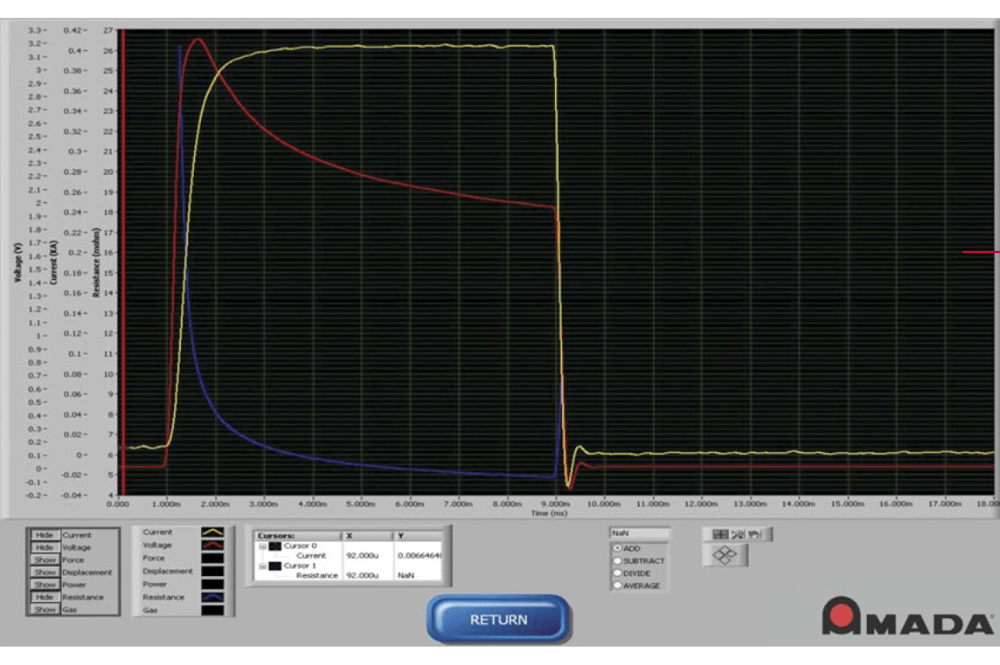

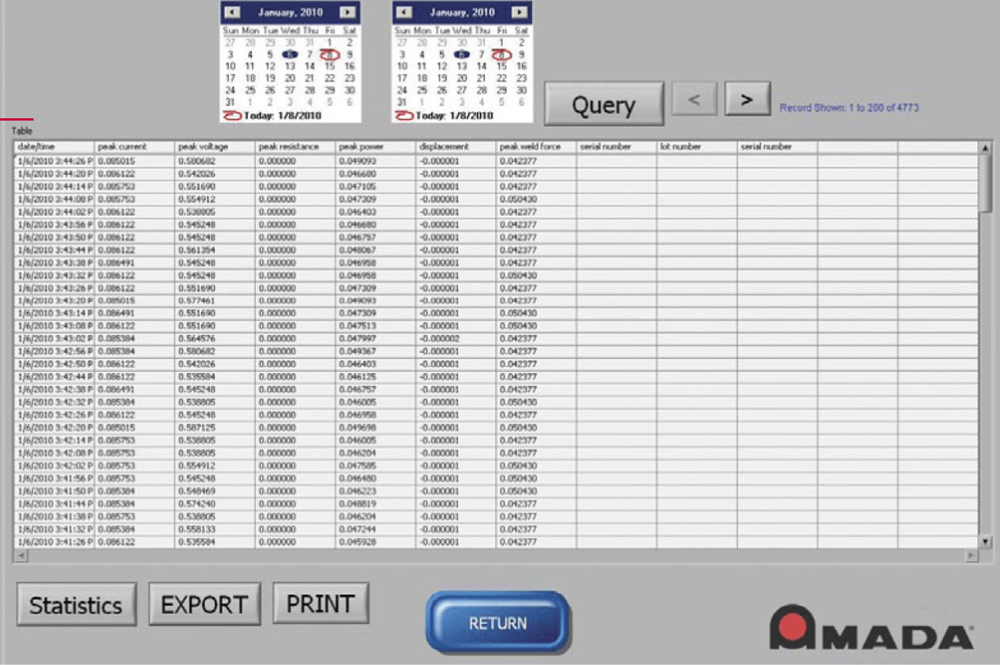

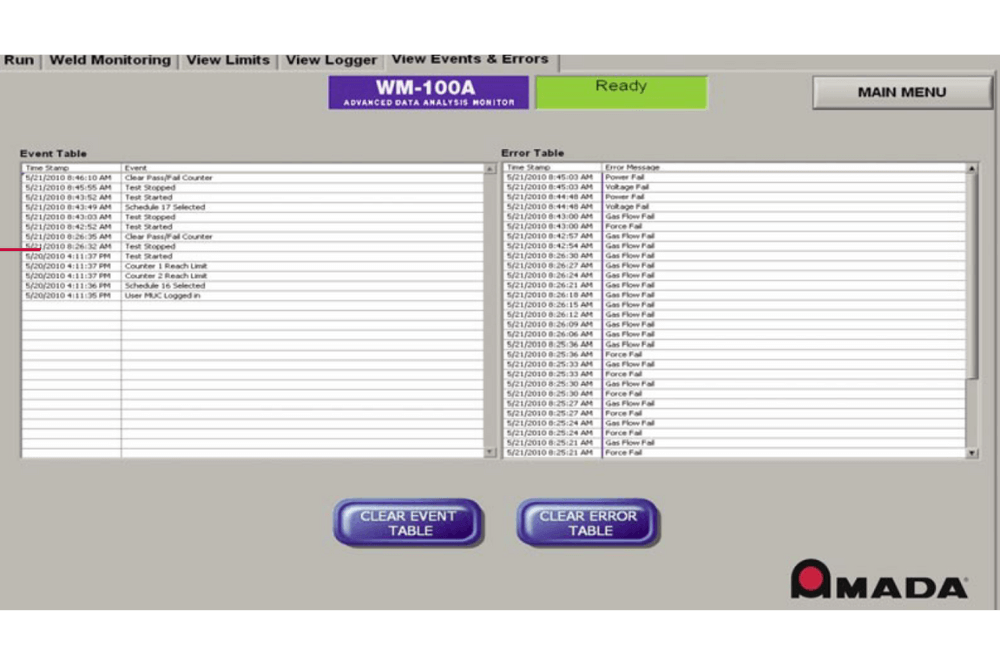

With an ever-increasing emphasis on accountability, AMADA WELD TECH’s WM-100A is the most advanced resistance welding monitoring system available from any manufacturer. Built in the USA, the WM-100A offers more of the information you need for resistance welding process development, production monitoring and data to support your ISO, and GMP and TQM requirements. Not only will it monitor what happens during the weld, but also before it is triggered, giving you a true 360-degree view of your welding process.

Technical Specifications

| M.O.L.E.™ EV6 | M.O.L.E.™ EV6 Baking | |

|---|---|---|

| Dimensions (L x W x H) | • Profiler: 152.4mm (6”) x 89mm (3.5”) x 9.41mm (0.37”) • Barrier: 269.7mm (10.62”) x 104mm (4.1”) x 26.9mm (1.06”) • Yellow Jacket: 286.5mm (11.28”) x 115mm (4.53”) x 32.5 (1.28”) | • Profiler: 152.4mm (6”) x 89mm (3.5”) x 9.41mm (0.37”) • BB-45: 241mm (9.5“) x 122mm (4.80“) x 46mm (1.82“) • BB-50: 238mm (9.37“) x 122mm (4.80“) x 49mm (1.93“) • BB-80: 236mm (9.3”) x 123mm (4.7”) x 80mm (3.15″) |

| Weight | • Profiler: 0.204 kg (7.2 oz) • Barrier: 0.861 kg (30.4 oz) • Yellow Jacket: 0.07 kg (2.4 oz) | • Profiler: 0.204 kg (7.2 oz) • BB-45: 1.47kg (51.85 oz) • BB-50: 2.38kg (83.95 oz) • BB-80: 4.1kg (144.60 oz) |

| Operational range (profiler) | -40°C to +85°C (-40°F to 185°F) | -40°C to +85°C (-40°F to 185°F) |

| Sampling interval | 100 samples/second to 10 minutes/sample | 100 samples/second to 10 minutes/sample |

| Data points | 16 million (2.6 million at 6 channels) or 200 data runs (whichever comes first) | 16 million (2.6 million at 6 channels) or 200 data |

| Accuracy | +/- 1°C (1.8°F) | +/- 1°C (1.8°F) |

Key Features

Simple and Immediate Status Confirmation

- On-screen instrument status display:

» Live temperature readings

» Thermal profile

» KPI table

Preventative Maintenance

- Built-in calibration reminders

- Battery life/charge indicators

- Memory status

Flexibility

- Supports multiple thermocouple types

Speed

- Sampling at up to 100 samples per second

Ease of Use

- USB C communications and charging

- 2-button control (on/off and record)

Operational Robustness

- High-capacity, off-the-shelf Lipo battery

- Auto shutdown protection for over temp conditions

- Programmable to conserve battery life

- Watchdog timer-monitored firmware control

- ESD-protected inputs

- Non-volatile profile memory

Interface

Key Industries

- Aerospace

- Automotive

- Defense

- Electronics

- Machinery & Manufacturing

- Medical

- Semiconductor, Solar & Electronics

Brand

The AMADA Group is a world leader in the manufacture of machines for sheet metal processing. Established in 1946 by Isamu AMADA, the Japanese Group has attained a unique position in the industry. AMADA not only manufactures machine tools, but also comes up with and proposes technological solutions to support the competitive edge of its Customers. With over 70 years of activities and experience and more than 90 companies, AMADA stands for technology and reliability.

Similar Products