Armfield – Chemical Engineering – CE Series

-

MALAYSIA

DKSH Technology Sdn. Bhd.

B-11-01, The Ascent, Paradigm, No. 1, Jalan SS7/26A, Kelana Jaya

47301 Petaling Jaya, Selangor

Malaysia -

SINGAPORE

DKSH Singapore Pte Ltd

625 Lorong 4 Toa Payoh, #03-00

319519 Singapore

Singapore -

VIETNAM

DKSH Technology

5th Floor, Viettel Complex, 285 Cach Mang Thang Tam Ward 12,

District 10/6th Floor, Peakview Tower,

36 Hoang Cau O Cho Dua Ward

70000 Ho Chi Minh City / Dong Da District, Ha Noi

Vietnam

Available Models

The Armfield CEXC family is a range of chemical reactors specifically developed for the teaching and demonstration of chemical reactor capabilities to chemical engineering students. Real chemical reactions take place within the reactors, and Armfield have developed a number of representative reactions which are easy and safe for students to use in the laboratory environment.

Key Features

- A self-contained benchtop service unit designed to provide services for up to five different chemical reactors:

- Continuous Stirred Tank Reactor

- Tubular Reactor

- Transparent Batch Reactor

- Plug flow reactor

- Laminar Flow reactor

- Fully computer controlled and supplied with educational software specific to each reactor type. Simple interfacing to the (user-supplied) computer by a USB interface

- Two peristaltic feed pumps with individually variable flow rates, 0-140 ml/min

- Provides PID temperature controlled hot water in order to maintain reactor temperature

- Complete with two thermocouples, an input for a third (user) thermocouple and a dual range conductivity sensor

- A comprehensive instruction manual is included, which details installation and operating procedures

The Armfield Stirred Tank Reactors in Series unit is designed to follow the dynamics of the perfectly mixed multi-stage process. Dynamic behaviour can be studied as can multi-stage chemical reaction.

Key Features

- A self-contained bench-mounted small-scale unit fitted with three continuous stirred reactors in series which are fed from two 5l tanks. Each reactor is fitted with a conductivity probe

- There are two independent, variable-speed feed pumps

- A dead-time residence coil can also be attached to the exit of the last reactor in the series

The Armfield Catalytic Reactors unit (CEU) utilises the sugar inversion reaction (Sucrose ➞ Glucose + Fructose) to study the performance of packed-bed chemical and biological catalytic reactors. A colorimetric assay is used to determine the degree of conversion using an optical sensor. Assays may be automated using optional flow injection analysis.

Key Features

- A benchtop unit comprising a vacuum formed ABS plastic plinth with integral electrical console on to which is mounted the packed-bed reactor columns, feed pump, optical sensor and optional flow injection analysis (FIA) system

- The unit is supplied as standard with two reactor columns for chemical catalysis

- An optional third column can be added to the system for biological (enzymic) catalysis

- A heated water supply to the column jackets allows automatic control of reaction temperature to a set point value

- Feed flow rate 0-15 ml/min

- The optional FIA pump can be adjusted to give flow rates up to 2.5 ml/min

- All electrical circuits are fitted with appropriate protection devices

- The console has two digital meters. The first, associated with the controller, shows the temperature of water supplied to the column jackets, and the second shows the optical sensor reading which provides a measurement of product concentration. Corresponding signals are routed to the I/O port for connection to a PC

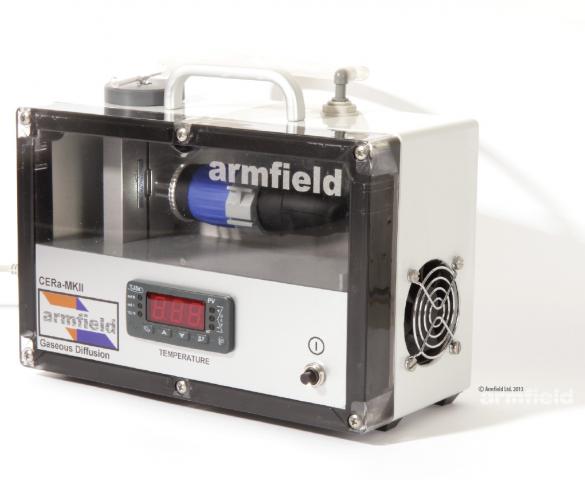

Armfield have yet again introduced a radical alternative to the traditional methods, utilising the benefits of modern computer-compatible microscopy, producing a novel system with a large number of benefits.

Apparatus for investigation of mass transfer and gaseous diffusion has traditionally used a capillary tube in a hot water bath, with a travelling microscope used to measure the rate of diffusion over a period of time. Although capable of giving good results, this type of apparatus was not without its disadvantages, particularly ease of use.

Key Features

- A self-contained bench-mounted apparatus for the determination of diffusion coefficients of a vapour in air

- The apparatus blows air across the top of the capillary tube, inside diameter 2mm

- The tube is contained in a heated aluminium block with a 25W heater

- The temperature control system maintains the temperature of the block to better than +/- 1°C from ambient to 60°C

- Operating temperature typically achieved in 20 min (40°C operation)

- The equipment incorporates a high-definition USB microscope with a resolution of 1600×1200 and preset to an optical gain of approximately x37

- Microscope and heater block containing the capillary are visible to the user and internal illumination of the capillary is provided

- Viewing length of the capillary is 12mm

- Physical reference scale provided (can be used for software calibration)

- Phase boundary measurement resolution < 0.0002mm

- Powered by universal power adaptor with worldwide approval

- Software can create individual images under operator control, multiple timed images under automatic control or timelapse video. Images can be time and date tagged. Timelapse periods can be set from five seconds to several days

- Output formats: .jpg .bmp .avi

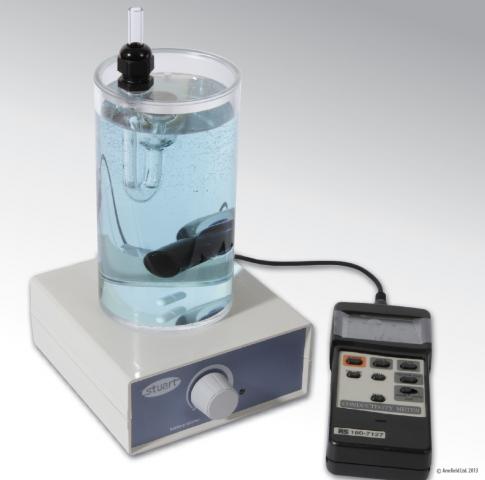

This laboratory equipment has been designed to enable measurement of molecular diffusivities and, in so doing, to familiarise students with the basic notions of mass transfer theory.

The liquid diffusivity apparatus (CERb) relates to an equimolar counter-diffusion process.

Key Features

- Accurate measurement of mass transfer rates in the absence of convective effects

- Use of Fick’s Law to deduce diffusion coefficients from measurements of mass transfer rate and concentration difference

- Simple analysis of a first-order unsteady state process effect of concentration

- on diffusion coefficients

- Gaining familiarity with the use of laboratory instruments to achieve accurate

- measurements of data required for industrial process design

- Windows data logging software included

The new CEKMkII is designed to facilitate the study of the factors affecting mixing. It uses a combination of visualisation and measurement techniques to enhance understanding.

Key Features

- A benchtop laboratory mixing system for demonstrating and teaching fundamental principles of mixing

- Electronically controlled variable speed drive system with accurate RPM measurement display

- Electronic measurement and display of torque on the drive head

- The drive can be varied from 50 to 2200rpm (note, not all the impellers are suitable for use at high speed)

- Impellers include a true Rushton turbine with eight alternate upward and downward-pointing vertical blades, a propeller and six different sizes of flat blades

- The flat blades are attached to a common mounting hub with a simple mechanism providing a precise blade angle. Seven different blade angles can be set for each blade size

- The Rushton turbine and flat-bladed impellers are manufactured from stainless steel

- Supplied with software to log the speed (RPM) and drive torque, calculate the power and display the data in graphs and tables

- A set of baffles is included

- The equipment can be operated in zero, two or four-baffle configurations

- An optional Heat Transfer Coil is available complete with temperature sensor and display

- Powered by a universal power adaptor with worldwide approval

For further information on the advanced features of the sophisticated Armfield software visit: www.discoverarmfield.co.uk/data/armsoft

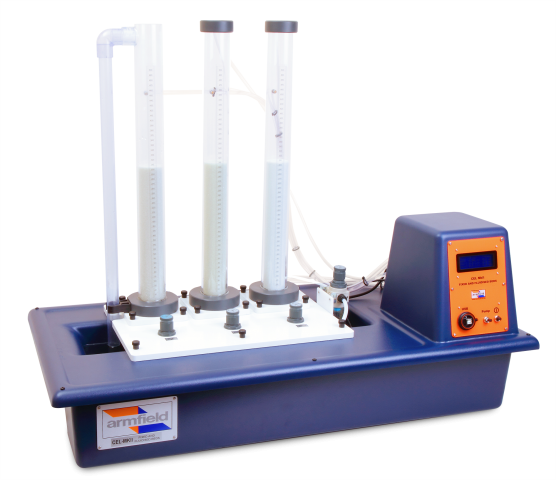

The CELMkII is designed to facilitate the study of flow through fixed and fluidised beds of solid particles.

This new improved MkII version has three columns, one for use with water and two for use with air. The separate air and water columns enable the difference between ‘aggregative’ and ‘particulate’ fluidized bed characteristics to be demonstrated. The two air columns enable the effect of different packing material sizes to be demonstrated without having to remove, empty and repack a column.

The MkII version also benefits from full electronic instrumentation and powerful armSOFT data logging software.

Key Features

- A benchtop apparatus for the study of fixed and fluidized beds of solid particles

- Three cylindrical columns, one for water and two for air, each column with a diameter of 50mm and height of 550mm

- Columns mounted above a blue ABS moulded base containing an 8l water reservoir

- Two sizes of bed material supplied, ranges: 0.5-0.75mm and 0.2-0.3mm

- Complete with a demonstration of liquefaction and how the properties of liquefied particles change with agitation

- Variable-speed submersible pump to recirculate water, rate up to 2 l/min

- Each column has tapping points and differential pressure sensors

- Air flow rate measured by orifice pressure sensors, the flow rate being calculated by an integral microcontroller

- Electronic front panel display shows flow rates and pressure drops for all three columns simultaneously

- Powered by universal power adaptor with worldwide approvals

- Supplied with powerful data logging software (PC not supplied)

Wetted wall columns may be used to determine gas/liquid mass transfer coefficients, essential when calculating the design of absorption towers. Such coefficients form the basis of correlations used to develop packed towers.

CES examines the absorption of oxygen from air into deoxygenated water (prepared by nitrogen sparging). This is an example of liquid-film controlled absorption. The liquid-film mass transfer coefficient can be determined at various mass flow rates of water.

Key Features

- A floor-standing apparatus, used for demonstration and determination of liquid-film mass transfer coefficients

- Comprises both wetted wall column and a deoxygenating column, a water tank, two water pumps, an air pump and an oxygen meter with two probes

- The wetted wall section is 900mm long, 32mm internal diameter, and made of glass

- The deoxygenating column is 1,570mm long, 26mm internal diameter, and made of clear acrylic

- The equipment is used to study absorption of oxygen from air into deoxygenated water, specific demonstrations include:

- Calculation of liquid film mass transfer coefficient

- Variation of this coefficient with mass flow rate

- Determination of the power-law relationship

Corrosion represents a significant factor in determining durability and safety of industrial processes. Student engineers need to understand fully the effects of corrosion and how these can be anticipated and prevented.

The Armfield Corrosion Studies Kit is designed to provide an introduction to this topic and allows students to recognise potentially corrosive situations and develop information to permit the selection of adequate materials.

Key Features

- The Corrosion Studies Kit allows simultaneous study of up to eight corrosion cells each containing three test specimens

- Sample mounting in a manner to minimise secondary effects

- Corrosion rates measured visually and by weighing

- Stirring by air or inert gas

- Comprising:

- A service panel

- Air pump

- Eight test cells of glass construction, with specially machined lids enabling samples to be mounted

- Test cell supports

- Digital pH meter

- Specimen pieces of steel, zinc, brass and copper

- Platinum electrodes

- Low voltage supply

- Associated glassware, tubing and wiring

The CEN comprises a variety of items which introduce different aspects of solids behaviour. The characteristics of the flow of solid materials are relevant to many process industries, particularly in handling powders, pellets, crystals and aggregates.

The flow and handling characteristics of granular materials are relevant to many process industries, particularly in the handling of powders, pellets, crystals and aggregates. The CENMkII introduces students to the behaviour of granular materials and is available as three units that can be purchased separately or as a complete set.

Key Features

- Exercises split between three separate units allowing only relevant equipment to be purchased or simultaneous use by more than one group of students at a time

- Hele-Shaw cell employed to give clear and accurate measurement of angle of repose and to demonstrate the behaviour of mixtures of different grains

- Ball mill and V blender operate inside a protective enclosure to minimise risk to the operator from rotating components or dust

- Ball mill and V blender can be quickly disconnected from the drive arrangement and easily removed from the protective enclosure to aid filling, emptying and cleaning

- Hele-Shaw cell, ball mill and V blender all constructed using clear acrylic where practicable to aid viewing

- Enclosure for CEN-MkII-11 and backboard for CEN-MkII-12 constructed from durable PVC plastic for serviceability

- Vibratory shaker with sieves allows different particle sizes to be seperated

CEN-MKII-11: Solids Handling incorporating ball mill and V blender

CEN-MKII-12: Powder Handling incorporating angle of repose cylinder, cylindrical hopper with orifices and pneumatic conveyor with cyclone

CEN-MKII-13: Variable intensity vibratory shaker and sieves

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Oil & Gas

- Pharmaceutical

- Powders & Pigments / Coating

Brand

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and pharmaceutical industries. Used by many of the world’s leading corporations, Armfield systems enable researchers and product developers to replicate full-scale industrial manufacturing processes on a miniature-scale in the laboratory.

Similar Products

Download now