Armfield – Miniature-Scale Research & Development Technology – FT102X Carbonator/Filler and FT104X Filler/Capper

The Armfield FT102X miniature-scale carbonator enables precise and flexible carbonation and filling in the laboratory, dramatically improving the speed with which new products can be developed. The ability to establish precise and reproducible parameters when carbonating in the laboratory can dramatically improve the speed with which new products can be developed.

The Armfield FT102X miniature-scale carbonator provides the ability to establish precise and repeatable parameters when carbonating in the laboratory, this can dramatically improve the speed with which new products are developed.

The FT102X is a totally new design including a large number of improvements and enhancements. In particular, special attention has been given to the ease of use, enhanced flexibility, reliability and improved Clean in Place (CIP).

Both premix and postmix operations are available from the standard machine, and an option is available to add the syrup for postmix automatically. Other options allow for deaeration of the product and evacuation of the bottles, continuous processing capability, and filling and capping (screw and/or crown) at a single station without removing the bottle.

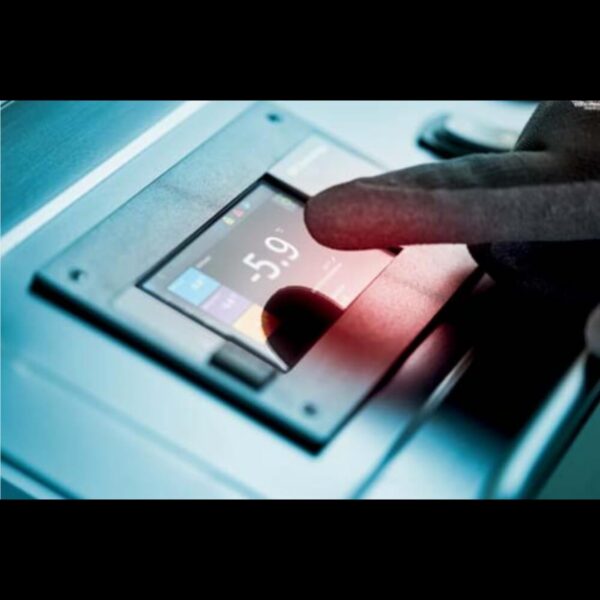

The FT102X Carbonator/Filler is easy to install, set up and use. Colour touchscreen control is used with a new graphical interface, enabling different carbonating and filling scenarios to be set and stored. The improved semi-automated cleaning programme takes the user step by step through the cleaning process and enables the unit to be made ready for another product or formulation.

The FT102X is ideally suited as a general-purpose filling and carbonation installation for small laboratory applications. Used in conjunction with one of Armfield’s FT74 UHT/HTST units, a complete drinks line can be created in the laboratory; consisting of heat treatment, carbonation, filling and capping.

Available Models

Key Features

FT102X Carbonator/Filler and FT104X Filler/Capper

Key Features

- Accurate control of filling and carbonating variables

- Option of filling and crown-seal capping and/or screwtop capping at a single station

- 30l process vessel, positioned at a convenient height

- Throughputs up to 60 l/h achievable (2l bottles) on FT102X

- Higher throughputs possible with add-on filling/capping system (FT104X)

- Wide range of cans or bottles can be used from 0.15l to in excess of 2.0l

- Evaluation service for customer cans and bottles

- CO2 content in excess of 10 g/l can be realised

- Enhanced colour touchscreen control with Help facility as standard

- In-bottle pressure measurement enables accurate and reproducible depressurisation

- Many parameters can be automated

- Carbonates foaming products

- Carbonates at any temperature between 4°C and 20°C

- Premix and postmix capability

- Adds protective gases (N2 connection now standard)

- Improved cleaning programs with heater and spray ball

- Fills non-carbonated drinks

Benefits

- Easily reproducible test batches

- Very flexible and accurate

- No CO2 loss during filling due to double-stage cooling

- Easy to use: many functions automated

- Cost saving: for small test batches no production line is required

- Additional filling/capping head (FT104X) can be added at a later date

- With FT104X different container styles can be filled and capped to individual parameters on the same product run

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Oil & Gas

- Pharmaceutical

- Powders & Pigments / Coating

Brand

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and pharmaceutical industries. Used by many of the world’s leading corporations, Armfield systems enable researchers and product developers to replicate full-scale industrial manufacturing processes on a miniature-scale in the laboratory.

Similar Products