Armfield – Miniature-Scale Research & Development Technology – FT51 Continuous In-line Deaerator

The Armfield FT51 deaerator unit has been designed to enable small quantities of food and other liquid products to be processed conveniently in the laboratory. It can be used as a standalone batch deaerator or inline with one of the Armfield continuous processing systems, such as the FT74XTS or the FT174X. The unit is designed to mirror the industrial processes of vacuum deaeration.

The FT51 may be sited in most production environments and is well suited to operation in the laboratory. Typical product throughput is 20 l/hr.

The FT51 offers both batch, where spray or disc-based deaeration can be undertaken, or a continuous mode, where the system can be used in conjunction with other Armfield processing equipment.

Key Features

FT51 Continuous In-Line Deaerator

Key Features

- Batch processing

- Continuous in-line processing

- Nitrogen degassing facility

- Autofilling of vessel

- Clean In Place (CIP)

- Easy to use

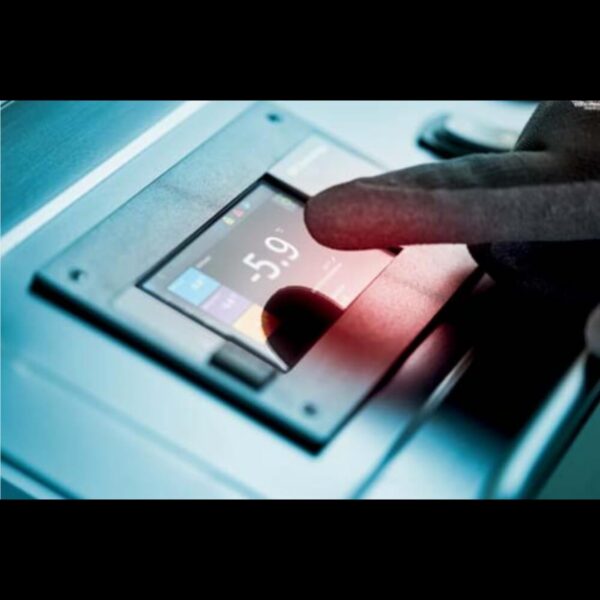

- Touchscreen control

- Full colour high resolution (800 x 480)

- Displays process flow diagrams and actual status

- Automatic operation

- Full compatibility with existing Armfield UHT systems

- Controllable vacuum level

- Spray or disc deaeration (batch mode only)

- Integrated water feed control for ease of UHT start-up

- Vacuum levels down to -0.95 bar

- Deaeration capabilities of down to 0.5ppm dissolved O₂ (batch mode with N₂ degassing)

Benefits

- Enhancement of product appearance (texture, colour and/or clarity)

- Preventing possible oxidation of colours, flavours, or nutritional compounds during heat treatment

- Improving shelf-life by reducing in-package oxidation risks

- Reducing potential usage of antioxidants in packaged products

- Reducing foaming during processing and/or filling

- Improving accuracy and reducing package volumes during filling

- Removing dissolved gases enabling increased carbonation levels in carbonated products

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Oil & Gas

- Pharmaceutical

- Powders & Pigments / Coating

Brand

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and pharmaceutical industries. Used by many of the world’s leading corporations, Armfield systems enable researchers and product developers to replicate full-scale industrial manufacturing processes on a miniature-scale in the laboratory.

Similar Products