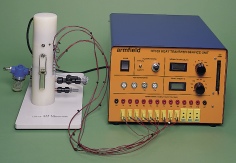

Armfield – Heat Transfer – HT10XC Computer Controlled Heat Transfer Teaching Equipment

The Armfield HT10XC is a computer controlled service unit, which can be used in conjunction with a range of small-scale accessories for a wide range of demonstrations into the modes of heat transfer. The factors that affect heat transfer can be investigated and some of the practical problems associated with the transfer of heat can be clearly demonstrated. The heat transfer accessories may be individually connected to the HT10XC service unit, which provides the necessary electrical supplies and measurement facilities for investigation and comparison of the different heat transfer characteristics. A specific feature of the HT10XC is that it corporates the facilities and safety features to enable the accessories to be remotely controlled from an external computer, where this is appropriate. It will shut down safely in the event of a communications failure. With suitable (user provided) software, the equipment operated remotely, for instance over an intranet or even over the internet. All the facilities can also be accessed locally using the front panel controls and display.

The service unit is housed in a robust steel enclosure and designed for use on a bench or table. It provides control outputs to the accessories, and instrumentation inputs from the accessories.

Outputs:

- A stabilised, variable DC supply to the heater of the heat transfer accessory under evaluation

- Drive to flow-regulation valves on HT11C and HT12C

- Drive to the variable-speed air blowers used on HT14C and HT16C

Inputs and Instrumentation:

- Temperatures: (up to 10 off, dependant on accessory being used)

- Heater voltage: (All accessories except HT17)

- Heater current: (All accessories except HT17)

- Heat radiated: (HT13)

- Light radiated: (HT13)

- Air velocity: (HT14, HT14C, HT16, HT16C,HT19)

- Cooling water flowrate: (HT11C, HT12C, HT18C)

In manual mode, the outputs listed above are under control of potentiometers on the front panel of the unit. In remote mode the outputs to the accessories are controlled by the computer. A ‘Watchdog’ system is implemented in remote mode to ensure operator and equipment safety in event of a computer or communications failure.

In both modes the signals from the accessory can be shown on the front panel displays. Selector switches are used to select the chosen signal onto one of the two displays. These signals are also available on the USB interface for datalogging on the computer (even if the computer is not controlling the equipment).

Available Models

Key Features

HT10XC Computer Controlled Heat Transfer Teaching Equipment

- A benchtop service unit designed to interface to a range of heat transfer accessories

- Provides a variable, stabilised 0-24V DC supply to the heater of the heat transfer accessory, with a current capability of 9 amp

- Provides a drive signal for a proportioning solenoid valve used for flow control

- Provides a control signal to a variable speed blower used for generating airflow

- 10 temperature inputs and conditioning circuits for K-type thermocouples:

- – 9 off, 0-133°C, resolution <0.1°C

- – 1 off, 0-500°C, resolution <0.15°C

- Instrumentation inputs for heater voltage, heater current, air flow, water flow, radiation and light meter

- Integral USB interface, and educational software for all accessories

- Outputs can be controlled manually from the front panel, or controlled by the software from a user supplied PC

- Watchdog circuit for operator and equipment safety in case of computer or interface failure when being controlled remotely(e.g. over a network or the internet using user written software)

- Easy interfacing to 3rd party software eg LabView, MatLab

- A comprehensive instruction manual describing how to carry out the laboratory teaching exercises in non-steady state heat transfer and their analysis as well as assembly, installation and commissioning is included

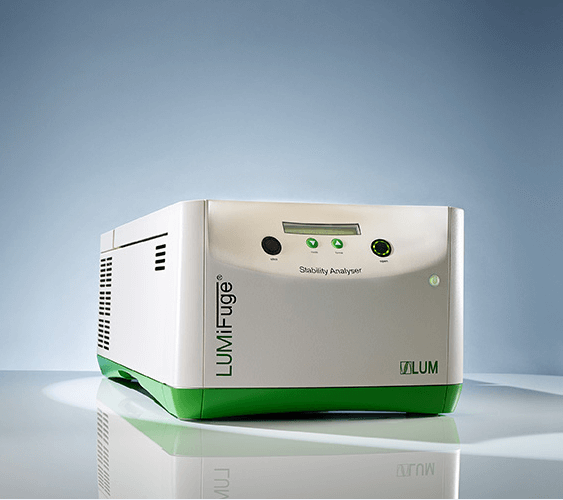

Key Industries

- Biopharmaceutical and Biotechnology

- Chemical

- Cosmetics & Personal Care

- Education & Academics

- Food & Beverage

- Oil & Gas

- Pharmaceutical

- Powders & Pigments / Coating

Brand

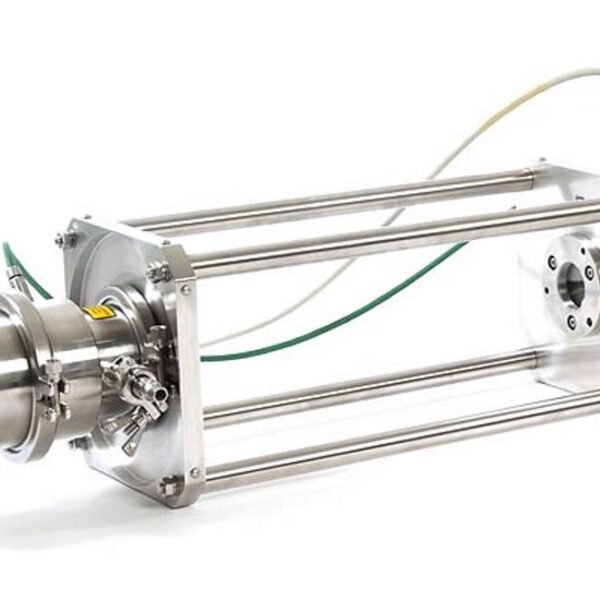

The Armfield Industrial Division designs and manufactures research & development systems, primarily for the food, beverage, dairy, edible oil and pharmaceutical industries. Used by many of the world’s leading corporations, Armfield systems enable researchers and product developers to replicate full-scale industrial manufacturing processes on a miniature-scale in the laboratory.

Similar Products