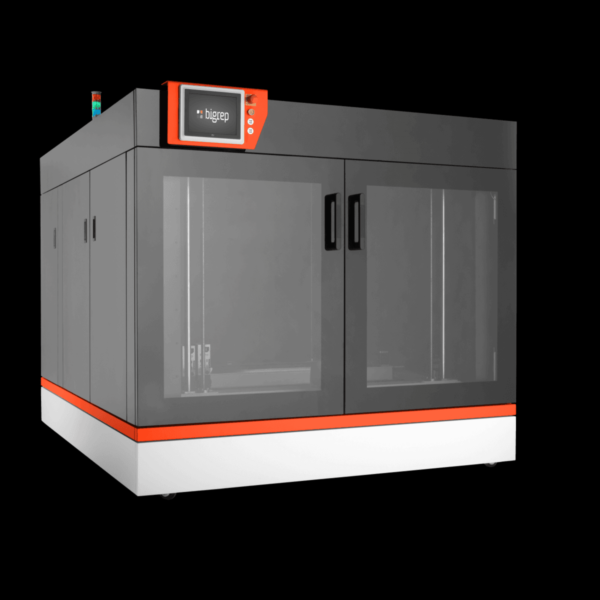

BigRep – 3D Printer – BigRep PRO

Large-scale and German Engineered

BigRep is pleased to introduce the latest addition to its range of additive manufacturing solutions – the BigRep PRO. German-made for speed and precision, the PRO is a machine for industrial solutions.

BigRep has designed and manufactured a machine that prints with engineering-grade materials to ensure users can manufacture the applications they need, in large scale. The PRO is an industrial 3D printer that responds to market demands.

Whether it’s functional prototypes, composite tooling or end-use products, the PRO delivers, with a range of new features, including a state-of-the-art Bosch CNC system, new Metering Extruder Technology (MXT®), an enclosed build chamber and temperature-controlled filament chambers.

The PRO was inspired by the ONE and STUDIO 3D printers, winners of multiple awards including the German Brand Award 2018, the German Innovation Award 2018 and the German Design Award 2016.

Technical Specification

| Build volume | x 1005 y 1005 z 1005 (mm) |

| Layer height resolution | 0.1 mm – 0.8 mm* |

| Max. Extruder Throughput with 1 mm nozzle | 500 cm³/h |

| Extruder | Two MXT extruders |

| MXT with 1 mm nozzle | MXT with 1 mm nozzle |

| Printing technology | FFF – Fused-Filament-Fabrication (Material Extrusion) |

| Certified BigRep materials | ASA, PA6/66 |

| More engineering materials in development | More engineering materials in development |

| Support materials | Soluble Plastics |

| Print bed temperature | Max. 99 °C |

| Printer weight | Approx. 1550 kg |

| Size | x 1950 y 2430 z 1790 (mm) – (Without towerlight) |

| Power | 3 X AC 400 V, 50/60 Hz, 5100 W |

| Safety certifications | CE approved |

| *Depending on selected nozzle |

Key Features

bigrep PRO

Large-Scale Prints

The Build Platform

True to its name, BigRep makes machines for big prints, and the PRO is no exception. With a build envelope of one cubic meter, the machine is made for 3D printing of large-scale industrial objects, enabling countless application possibilities.

Shielded Printing

The Enclosed Frame

An insulated enclosed metal frame ensures optimum even temperature control and the glass doors offer an optimal view on the print. Further improving safety is the PRO’s compatibility with standard ventilation systems, for fume and emissions control, making it a best practice example for 3D printing in industrial environments.

Industrial Material Compatibility

The Insulated Filament Cabinet

The PRO provides an optimal environment for printing with industrial-grade materials, due to a humidity controlled spool chamber. Air circulation fans within ensure air flow for uniform temperature throughout the filament cabinet, and the cabinet stores up to four filament spools.

Speed & Precision

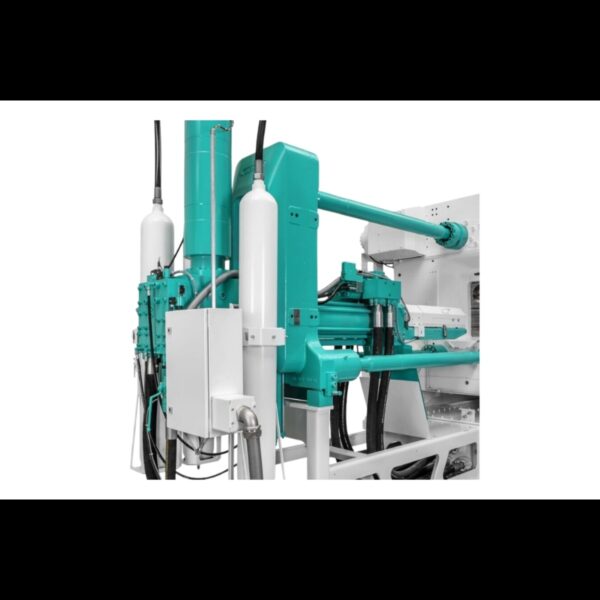

The MXT®

BigRep is introducing a metering extruder technology (MXT®) with exceptional speed and precision, which is one of the defining features of the PRO. This state-of-the-art extruder allows for ultimate control on the materials deposition, allowing users to achieve the highest quality for every application.

Semi-Automatic Leveling

The Print Bed

The heated print bed mounted with polyimide foil provides optimal adhesion in the printing process. An integrated inductive sensor allows for semi-automatic leveling of the print bed.

Bosch Rexroth Technology

The CNC System

A new state-of-the-art Bosch CNC motion- control system makes the PRO the ideal machine for controlling the entire printing process, from start to finish. Widely used in the automotive industry, the Bosch system ensures maximum responsiveness, accuracy and closed-loop control in BigRep’s industrial-grade machine, as well as superior connectivity.

Redefining Additive – BigRep PRO

Key Industries

- Aerospace

- Automotive

- Die & Mould

- Education & Academics

- Electronics

- Machinery & Manufacturing

- Medical

- Mining & Minerals

- Oil & Gas

- Semiconductor, Solar & Electronics

- Shipbuilding

Brand

Founded in 2014, BigRep set sail to transform the 3D printing and manufacturing business. With its 1m3 volume, the BigRep ONE opens the gateway to a new dimension of 3D printing and 3D manufacturing, while the BigRep Studio allows fast and precise large-scale 3D printing.

From furniture to vehicles to robotics, we think everything is possible. We want you to envision everything from human scale robot parts, sculptural artworks in all their full-dimensional glory, and dream the impossible world-changing designs of tomorrow while enabling you to print them today using one of our 3D printers.

Similar Products