Felsomat – Automation Storage Systems – FSC600

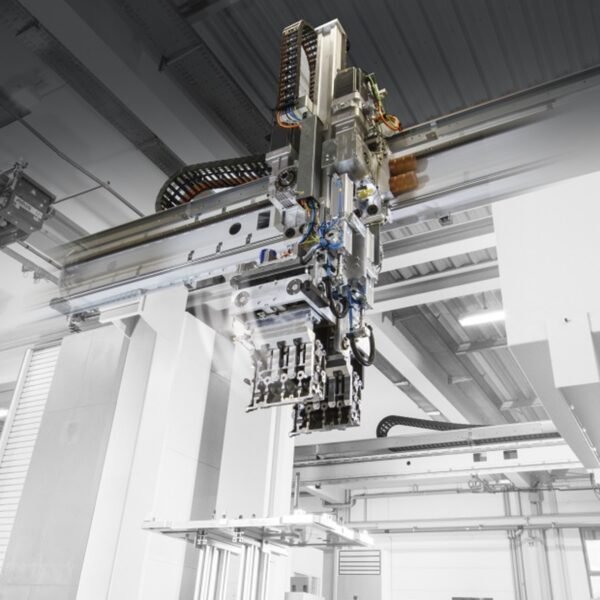

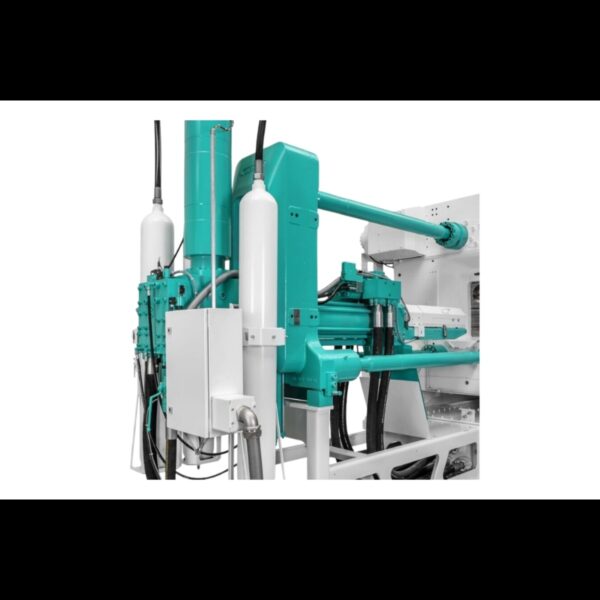

The Felsomat stacker cell with its unique functional design offers possibilities for the material flow of manufacturing lines which are rarely realized with other decoupling modules. The palletizer unit works in two stacking directions, and it is therefore possible to introduce and retrieve stacks at the same position making a central interface for the operator and eliminates unnecessary space required for loading the cell at multiple points. When the central loading door is open, a stack with finished components can be retrieved and a new stack with rough parts introduced into the loading bay of the cell. The stack change is confirmed at the control panel.

Product Description

The compact and modular stacker cell reduces the required floor space and gives maximum operation flexibility. The cell can be enhanced at any time in height, length and functionality and can be adapted for individual production requirements.

The organization of the material flow is quite simple. In the FSC the work pieces are supplied in a defined order in wire baskets on a trolley where they can be picked up by a gantry or robot. The baskets are handled with an integrated pick and place unit with a horizontal and vertical NC-axix. The cell operates autonomously and the fininished part / raw part exchange function can be performed without interruption of the machine loading sequence due to an integrated safety guard.

Technical Specifications

| robot | 30Kg payload, the scope of work according to customer site conditions | |

| the maximum workpiece diameterø | 300mm | |

|---|---|---|

| maximum workpiece height | 50mm | |

| maximum workpiece weight | 10kg | |

| pallet size | separate design according to the workpiece | |

| number of loads | depending on the number of pallets and the length of the bin | |

| *You can contact us for more parameters and product information. | ||

Key Features

Automation Storage Systems FSC600

- Compact design with small foot pring

- Scalable cell unit in width and length

- Work piece supply with an autonomous cell, freely configurable in relation to the position of the machine tool

- High inventory of parts per stack

- Loading of the baskets only once, there is no manual part handling required afterwards for downstream operations.

- No idle times at basket or stack exchange

- No need for a constant attentions by the operator at the cell

Contact Us

| Beijing 26th Floor, West Tower, Hanwei Plaza No.7 Guanghua Road, Chaoyang District, Beijing TEL: 010-6561 3988 FAX: 010-6561 0278 | Shanghai Room Unit 605-607, Build 2, Xinglian Building, No.1535 Hongmei Road, Xuhui District, Shanghai TEL: 021-5383 8811 FAX: 021-3367 8466 | Chengdu Room 802, 8/F, Tower 1, Central Plaza No.8 Shuncheng Street, Chengdu TEL: 028-8676 1111 FAX: 028-8676 1122 |

| Guangzhou Room 1213-1215, 12/F Jie Tai Plaza, 218-222 Zhongshan Road ,Guangzhou TEL: 020-8132 0662 FAX: 020-8132 0663 | Xi’an B-4-H, K.I.Tower, No.1 Xihuamen, Xi’an TEL: 029-8833 7412 FAX: 029-8833 7415 | Hongkong 23/F, Tower A, Southmark, 11 Yip Hing Street, Wong Chuk Hang, Hong Kong TEL: 00852-2880 9808 FAX: 00852-2369 1042 |

Key Industries

- Aerospace

- Automotive

- Machinery & Manufacturing

Brand

Reishauer products have been exported for decades into all industrialized countries in the world and prove themselves in small and midsize companies as well as in large corporations.

The aspiration, to offer not only machine tools but complete solutions for problems, is the constant driver for Reishauer. Even the highest demand in accuracy can be satisfied with Reishauer machines very economically.

The continuous generating gear grinding machines as well as the diamond and CBN tools are used for the manufacturing of superior products in the most efficient way. Special requirements in terms of accuracy, life time and uptime are no challenge for Reishauer machines.

To guarantee the best proximity to customers, we have a careful focus on an active sales network. Thus we are staying close to the actio

Similar Products