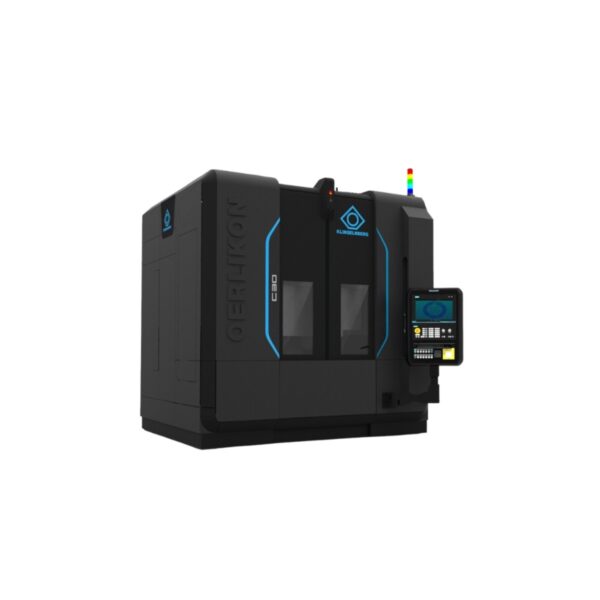

Georg Kesel – Bandsaw Blade Milling Machine – FS 1500

The compact powerhouse of the bandsaw and saw accessory industry, the FS 1500 is a common sight at the world’s best sawblade manufacturers. The perfect combination of performance and economical manufacturing ensures success in every application.

Based on decades of expertise in the bandsaw industry, the Kesel FS 1500 is capable of milling carbon and bimetal bandsaw blades up to 80 mm in band width and with 32 – 1.4 teeth per inch. Equipped with the state of the art Siemens SINUMERIK 840D sl control as well as Siemens drive units, the FS 1500 offers complete Industry 4.0 compatibility.

The fully enclosed cabin provides every aspect of safety, low noise emission and clean workshop conditions. With a robust and reinforced machine structure, the FS 1500 is capable of milling challenging tooth profiles within rapid cycle times.

With compatible coiling systems in either horizontal or vertical designs, the FS 1500 can be configured alongside a variety of material handling systems as part of a complete manufacturing line.

Technical Specification

| Bandsaw Data | Bandwidth | Up to 80 mm |

| TPI | 32 – 1.4 | |

| Milling Head | Type | F2-SK |

| Power | max. 315 | |

| RPM | SK 50 | |

| Max. Tool Width | 200 mm (Subject to cutter taper and rake angle) | |

| Milling Arbor | SK 50 according to DIN 2080 | |

| Control | Siemens SINUMERIK 840D sl | |

| Clamping System | Clamping | Hydraulic high pressure clamping unit with band levelling device |

| Max. packet width | 60 mm | |

| Dimensions and Weight | Installation dimensions (L x W x H) | 5,200 x 2,900 x 2,700 mm |

| Machine weight | Approx. 6,700 kg | |

| Options | Additional milling accessories Additional clamping equipment Coiling systems Cutter changing unit Further accessories upon request. |

Key Features

- Manufacture bandsaws and saw blades up to 80 mm in bandwidth.

- Mill 32 – 1.4 TPI tooth profiles with ease.

- A compact powerhouse with a world-class track record.

The Kesel DNA – Our Story

Situated within the world’s machine tool building heartland, Kesel have been been producing machines and clamping systems in Allgäu, Bavaria for over 130 years. What defines us from our competitors? It lies within our DNA. We don’t simply build machines, we develop world-leading technology. That makes us different. That makes us Kesel.

Key Industries

- Aerospace

- Automotive

- Defense

- Die & Mould

- Education & Academics

- Electronics

- Machinery & Manufacturing

- Medical

- Mining & Minerals

- Oil & Gas

- Semiconductor, Solar & Electronics

- Shipbuilding

Brand

Georg Kesel GmbH & Co. KG is an internationally recognized manufacturer of machine tools for linear tooth profile milling. These milling machines offer optimized production techniques for bandsaw blades, racks, steering racks, steering pistons and workpiece with customer specific tooth profiles. Our product range also covers setting machines, bandsaw blade straightening machines, coiling systems and gear deburring machines. Our second business division is clamping systems. The Kesel clamping technology covers mechanical, pneumatic and hydraulic machine vices and clamping systems including customer specific modifications.

Similar Products