Heraeus – Semray – UV LED

-

MALAYSIA

DKSH Technology Sdn. Bhd.

No. 108-B-01-08, Setia Spice Canopy, Jalan Tun Dr. Awang,

11900 Bayan Lepas, Penang

Malaysia -

SINGAPORE

DKSH Singapore Pte Ltd

625 Lorong 4 Toa Payoh, #03-00

319519 Singapore

Singapore -

THAILAND

DKSH (Thailand) Limited

2106 Fantree 4 Building, Sukhumvit Road,

Phrakhanong-Tai, Phrakhanong 10260 Bangkok

Thailand -

VIETNAM

DKSH Technology Co.,Ltd

5th Floor, Viettel Complex, 285 Cach Mang Thang Tam Ward 12,

District 10

70000 Ho Chi Minh City

Vietnam -

VIETNAM

DKSH Technology Co.,Ltd

5th Floor, Viettel Complex, 285 Cach Mang Thang Tam Ward 12,

District 10

70000 Ho Chi Minh City

Vietnam

Semray® UV LED Brochure

Semray® UV 4103 Brochure

Semray® UV 4103 Brochure

Semray® UV PC6003 Brochure

Our air- and water-cooled UV LED curing product portfolio offers different power classes and lamp head sizes to fit various industrial applications. To suit your process best, we have wavelengths from 365 nm to 405 nm available. Not only do we offer appropriate controlls and cooling systems, but also customized solutions to meet the customers unique needs.

Available Models

Technical Specifications

| Peak Wavelength 1) [nm] | 365, 385, 395, 405 |

| Typ. Irradiance2)3) [W/cm2] | 365: 3.3 385: 4.5 395: 5.5 405: 5 |

| Emission window [mm2] | 75 x 10 |

| Outer dimensions of housing (WxDxH) [mm3] | 77 x 120 x 28 |

| 1) Tolerance +/- 5 nm. 2) Value applies to maximum fan speed and maximum lamp current 3) Typical irradiance at emission window. |

The Semray® UV2000 Series is compact, lightweight and modular, ideal for low power applications. It can be used as a stand-alone unit or in combination with other UV LED light sources.

Technical Specifications

| Model | UV4103 Segment | UV4103-01 | UV4103-20 |

| Peak wavelength [nm] | 365, 385, 395, 405 | 365, 385, 395, 405 | 365, 385, 395 405 |

| Typ. Irradiance [W/cm²] | 365 nm: 13 385 nm: 15 395 nm: 18 405 nm: 17 | 365 nm: 13 385 nm: 15 395 nm: 18 405 nm: 17 | 365 nm: 13 385 nm: 15 395 nm: 18 405 nm: 17 |

| Typ. Optical Output [W] | 365 nm: 150 385 nm: 170 395 nm: 210 405 nm: 195 | 365 nm: 150 385 nm: 170 395 nm: 210 405 nm: 195 | 365 nm: 3.000 385 nm: 3.400 395 nm: 4.200 405 nm: 3.900 |

| Typ. Power Class | 365 nm: 20 385 nm: 23 395 nm: 28 405 nm: 26 | 365 nm: 20 385 nm: 23 395 nm: 28 405 nm: 26 | 365 nm: 20 385 nm: 23 395 nm: 28 405 nm: 26 |

| Emission Window [mm²] | 77 × 45 | 77 × 45 | 1.540 x 45 |

| Max. Power Consumption [W] | 550 | 550 | 11 |

| Weight [kg] | 1,5 | 2,6 | 41 |

| Outer Dimensions Of Housing (W × D × H) [mm3] | 77 × 135 × 253 | 112 x 136 x 253 | 1.575 x 136 x 253 |

Industrial curing processes are complex and require a lot of experience and application know-how. For this it is important to rely on a curing system, which also helps minimizing down time and still delivers a brilliant quality. Semray®UV4103 the new LED system is versatile applicable and fulfills many different curing process requirements, without sacrificing quality and performance.

The simple things are working best. That’s why we made things simple for you.

- ONE UV LED segment.

- ONE backplane.

- ONE data cable.

- ONE power cable.

- Independent of the width

Technical Specifications

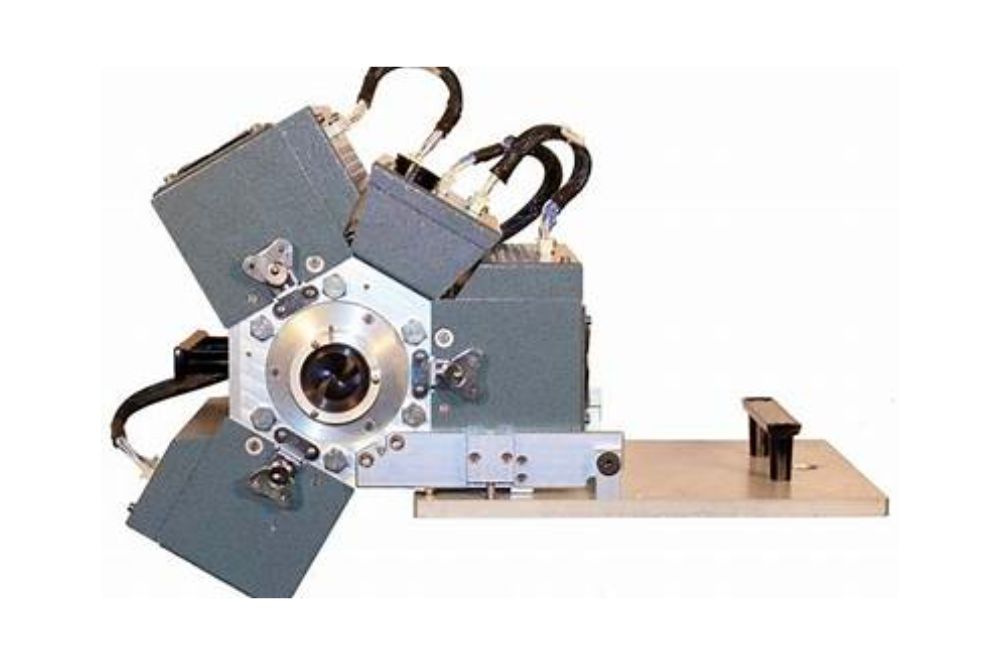

| Model | UV PC6003 |

| Wavelength [nm] | 395 |

| Irradiance at Target [W/cm2] | 65-70 |

| Emission length [mm] | 165 |

| Maximum Dimensions [mm] | 364 (W) × 265 (H) × 543 (L) |

Our new Semray® UV PC6003 LED curing system, goes above and beyond to meet production speeds while reducing downtime and lowering total cost of ownership. Plus we made retrofitting existing draw towers and other fiber and cable processing lines easy and cost effective. The typical payback for retrofitting a draw tower is about 2 years.

Key Features

- Faster production speeds versus other UV LED curing systems due to higher UV output and better uniformity

- Reduced downtime due to the long operating lifetime of LEDs, optimized thermal management, and quick and easy LED array module changes

- Easy to retrofit, drop-in replacement for existing microwave-powered UV curing systems

- Energy cost savings of 83% due to efficient LED technology and optimized optical design*

- Industry 4.0 ready with its embedded sensors and microprocessor data

- Easily monitor system performance to reduce unscheduled downtime and scrap rates using optional AIMS® software

- Lowest total cost of ownership due to lower operating and maintenance costs

*Energy savings as compared to an F600S microwave-powered UV curing system

Technical Specifications

| Model | UV5000+ Series |

| Peak Wavelength [nm] | 385 |

| Irradiation intensity [W/cm2] * | 365: 3.3 385: 4.5 395: 5.5 405: 5 |

| Irradiation intensity at 50 mm working distance | 16 |

| Emission window [mm2] ** | X × 82 |

| Outer dimensions of housing (WxDxH) [mm3] *** | X × 100 × 100 |

| * At emission window ** Emission window size scalable in width from 400 to 1300mm in 50mm steps *** Outer dimensions of housing scalable in width from 415 to 1315mm in 50mm steps |

The Semray® UV5000+ series rises this challenge and provides a unique solution for new and used presses. Unbeaten for industrial printing applications UV LED “+” is designed for a higher performance and a flexible integration. All components are perfectly matched to ensure a high and uniform UV output for optimum printing results – even at large working distance.

Key Features

- Highest output at 60 mm distance increases the printing speed dramatically

- Ozone and VOC-free technology requires no airflow section, which saves energy and space for blowers and additional pipework

- Powderless, no smear-off in the delivery pile saves costs and cleaning time

- Instant ON/OFF in milliseconds and pulsing possible, saves more than 10% of lamp energy

- Symmetrical switch off for smaller paper formats, half the paper size saves 50% energy of the lamp

- No spare parts are required which reduces maintenance costs

- Less heat transfer to heat-sensitive materials such as plastics

- Stable UV LED system operation reduces maintenance expenditures

- Immediate results allow fast turn over time from printing to delivery

8 Watts Are Not Always 8 Watts – Mean Power Density Is the Important Value

Key Industries

- Semiconductor, Solar & Electronics

Brand

The company’s roots go back to a family pharmacy started in 1660. Today, the Heraeus group includes businesses in the environmental, electronics, health and industrial applications sectors. Customers benefit from innovative technologies and solutions based on broad materials expertise and technological leadership.

Similar Products

Download now