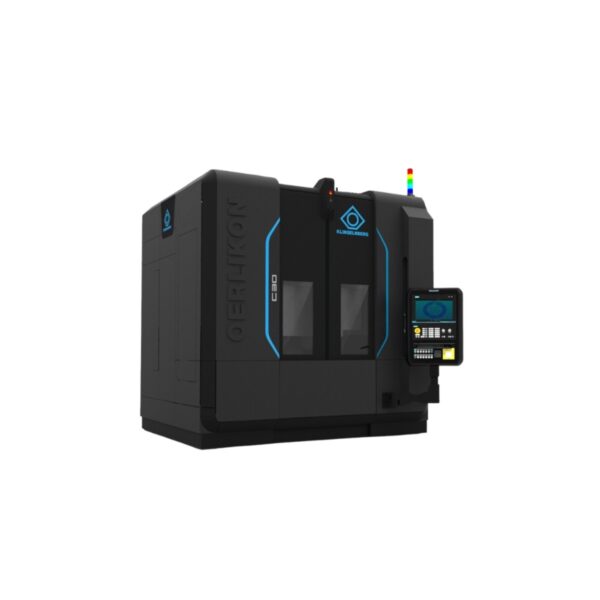

Klingelnberg – Bevel Gear Cutting Machine – Oerlikon C 30

Thanks to continuous further development of the vertical concept, the Oerlikon C 30 bevel gear cutting machine sets new standards in dry processing. All of the bevel gear machines in this series are equipped with a thermostable, vibration-damping machine bed. The cutting machine utilizes an optimized axis arrangement, resulting in reduced traversing paths that significantly reduce the load on the drive components and stiffen the structure of the overall system at the same time. An integrated deburring tool also provides maximum productivity and maximum process safety using the PULSAR method. Use of the optional Power Skiving method makes it possible to achieve even greater machine flexibility and productivity.

Range of Application

| Workpiece Data | Continuous Indexing | Single Indexing |

| Workpiece diameter (max.) | Ø 280 mm | Ø 280 mm |

| Normal module range | 1.5 – 6.5 mm | 1.5 – 6.5 mm |

| Cutter head diameter | 39 – 105 mm | 3,25“ – 7,5“ |

| Seating diameter: Oerlikon outer cone 1:4 | Ø 140.11 mm | Ø 140.11 mm |

| Seating diameter: Oerlikon inner cone No. 39; 1:19,764 | Ø 99.258 mm | Ø 99.258 mm |

| Machine dimensions (L x W x H) approx. | 4,150 x 3,420 x 2,850 mm | 4,150 x 3,420 x 2,850 mm |

| Net weight approx. | 16,000 kg | 16,000 kg |

Key Features

- Continuous further development of the vertical concept with minimal traversing paths

- New materials with optimal attenuation properties while providing an extremely stiff structure and thermal stability

- Integrated deburring in the same clamping as for gear cutting

- New operating software with touchscreen display and clear screen layout

- Vertical spindle arrangement makes clamping device changes easy

- Optional Power Skiving of internal and external gearing by means of cylindrical monoblock tools

- Optimal energy efficiency (e2) thanks to recovery and on-demand control of units

Contact Us

| Beijing | Shanghai | ||

| 26/f, West Tower Hanwei Plaza, No.7 Guanghua Road, Chaoyang District, Beijing | Tel:010-6561 3988-160 E-mail:gem.cn@dksh.com | Unit 5-7, 6f, Build 2 Xinglian Building, N0.1535 Hongmei Road, Xuhui District, Shanghai | Tel:021-5383 8811-116 E-mail:gem.cn@dksh.com |

Key Industries

- Automotive

- Shipbuilding

- Agriculture

- Machinery & Manufacturing

- Aerospace

Brand

The Klingelnberg Group is a world leader in the development, manufacture and sale of machines for bevel gear and cylindrical gear production, measuring centers for gearing and axially symmetrical components as well as customized high-precision gear components. The Company’s products are used by customers in automotive, truck, aircraft, agriculture, construction, power tool and marine industries and by a diverse set of customers serving various industrial equipment markets.

Similar Products