Maegerle – MGC Workpiece Carrier

-

SINGAPORE

DKSH Singapore Pte Ltd 625 Lorong 4 Toa Payoh, #03-00 319519 Singapore Singapore

+65 6274 1222

+65 6273 1503

Available Models

Technical Specifications

| X-axis longitudinal stroke | 800…5500 mm |

|---|---|

| X-axis travel speed | 0…20000 mm/min |

| Y-axis vertical stroke | 450…900 mm |

| Y-axis travel speed | 0…10000* mm/min |

| Z-axis transverse stroke | 350…750 mm/min |

| Z-axis travel speed | 0…10000* mm/min |

| V-axis profile crushing device, roll width, max. | 167…307 mm/min |

| Roll diameter max. | 160mm |

| Roll drive AC drive max. | 6000 rpm |

| Grinding spindle drive – power | 25/50/75/115** |

| Rpm range | 5000 (8000) rpm |

| Grinding wheel peripheral speed | 35 m/s |

| – with key-operated switch switchable to | 50 m/s |

| – with additional flange monitoring switchable up to | 63 m/s |

| Grinding wheels – diameter | 400…600 mm |

| Grinding wheels – width | 160…300 mm |

| Fixed table L x W | 800…5500 x 500/750 |

| *optionally | 20 m/min |

| **max. spindle power is dependent on size | |

| (subject to technical modifications) |

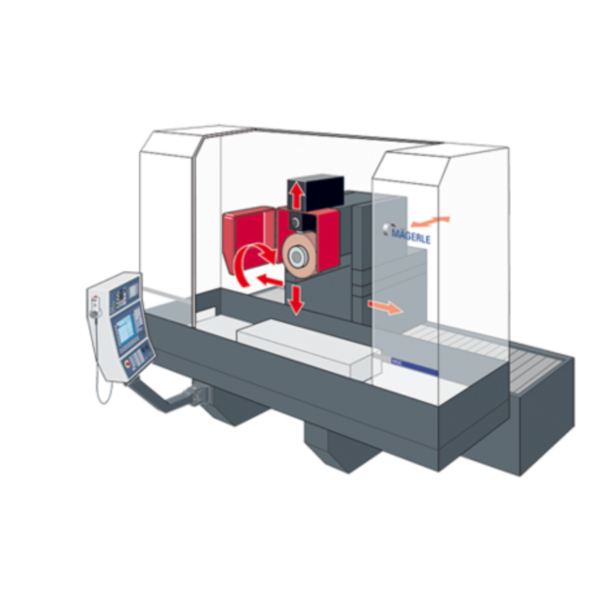

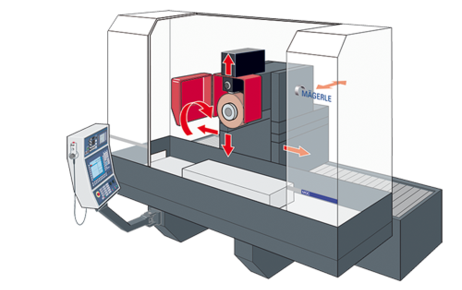

Like all models in the MGC series, this grinding centre is also based on the proven modular concept. Thanks to its variety of configurations with one or several spindles in a horizontal or vertical arrangement as well as a multitude of additional components, the MGC with fixed console is also one of the front-runners in its category with regard to flexibility.

Applications:

- Impellar

- Precision steering rack

- Corrugating Roll

- Carriage for linear guideway

- Edging tools

Technical Specifications

| X-axis longitudinal stroke | 800…3300 mm |

|---|---|

| X-axis travel speed | 0…20000 mm/min |

| Y-axis vertical stroke | 450…1200 mm |

| Y-axis travel speed | 0…10000* mm/min |

| Z-axis transverse stroke | 350…750 mm/min |

| Z-axis travel speed | 0…10000* mm/min |

| V-axis profile crushing device, roll width, max. | 167…307 mm/min |

| Roll diameter max. | 160mm |

| Roll drive AC drive max. | 6000 rpm |

| Grinding spindle drive – power | 25/50/75/115** |

| Rpm range | 5000 (8000) rpm |

| Grinding wheel peripheral speed | 35 m/s |

| – with key-operated switch switchable to | 50 m/s |

| – with additional flange monitoring switchable up to | 63 m/s |

| Grinding wheels – diameter | 400…600 mm |

| Grinding wheels – width | 160…300 mm |

| Swivelling table +/- 180° with 2 clamping surfaces | 760…1150 x 325…600 |

| *optionally | 20 m/min |

| **max. spindle power is dependent on size | |

| (subject to technical modifications) |

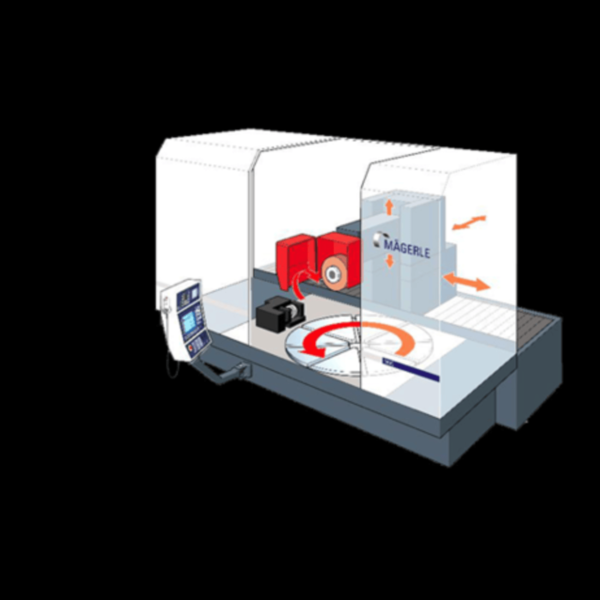

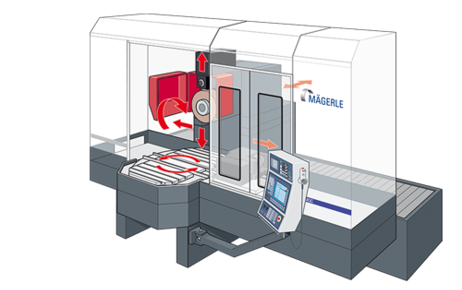

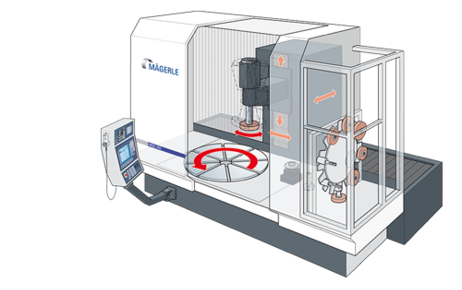

Like its sister systems in the MFP series, the Mägerle Grinding Center delivers superb results for creep feed grinding with high removal capacities as well as for profile and flat grinding. In its swivelling table version, the MGC is also designed with the maximum ejection capacity. The 180° swivelling table allows loading and unloading of workpieces while machining is in operation. Non-productive times for workpiece change are thus largely eliminated. This results in maximum productivity for small and large batches, as well as in special applications. The MGC with swivelling table, in conjunction with the automatic loading and unloading system, frees up additional reserves. The openly accessible swivelling table also provides the ideal interface.

Applications:

- Turbine rotor vane

- Rotors

- Pump rotors

- Rocker arm

- Spring collets

- Steering rack variations

- Projectile body

- Shearing knife

- Textile industry

- Saw blades

Technical Specifications

| X-axis longitudinal stroke | 1400…2600 mm |

|---|---|

| X-axis travel speed | 0…20000 mm/min |

| Y-axis vertical stroke | 450/650/900/1200 mm |

| Y-axis travel speed | 0…10000* mm/min |

| Z-axis transverse stroke | 500…750 mm/min |

| Z-axis travel speed | 0…10000* mm/min |

| V-axis profile crushing device, roll width, max. | 167…307 mm/min |

| Roll diameter max. | 160 mm |

| Roll drive AC drive max. | 6000 rpm |

| Grinding spindle drive – power | 50/75/115** |

| Rpm range | 5000 (8000) rpm |

| Grinding wheel peripheral speed | 35 m/s |

| – with key-operated switch switchable to | 50 m/s |

| – with additional flange monitoring switchable up to | 63 m/s |

| Grinding wheels – diameter | 400…600 mm |

| Grinding wheels – width | 160…300 mm |

| Rotary table-Ø | 760…1150 x 325…600 |

| *optionally | 20 m/min |

| **max. spindle power is dependent on size | |

| (subject to technical modifications) |

With table diameters of up to 2.5 metres and a maximum load bearing capacity of 12 tons, the MGC rotary table grinding centre is unequalled throughout the world. Well-known companies in the power turbine industry rely on this powerful concept. This grinding centre is unrivalled particularly when it comes to machining turbine blades with Hirth gears and Curvic couplings of the highest quality. The direct-drive rotary table mounted on hydrostatic bearings ensures the necessary precision, with a positioning accuracy of less than three angular seconds.

Applications:

- Adapterring

- Hirth gear

Technical Specifications

| X-axis longitudinal stroke | 1400…2600 mm |

|---|---|

| X-axis travel speed | 0…20000 mm/min |

| Y-axis vertical stroke | 450…1200 mm |

| Y-axis travel speed | 0…10000* mm/min |

| Z-axis transverse stroke | 500 mm |

| Z-axis travel speed | 0…10000* mm/min |

| Grinding spindle drive – power max. | 30 kW |

| Rpm range | 0…15000 rpm |

| Grinding wheel peripheral speed | 35 m/s |

| – with key-operated switch switchable to | 50 m/s |

| Tool changer positions – grinding wheels | 1…16 |

| Tool changer positions – measuring probe, drill | 1…24 |

| Grinding wheel dimensions (external Ø x width x bore Ø) | 300 x 150 x 76.2 mm |

| Tool holding fixture | HSKB-80 |

| Rotary table-Ø | 800…1500 mm |

| *optionally | 20 m/min |

| (subject to technical modifications) |

Versatility with the highest production quality level is the outstanding strength of this vertical grinding machine. It demonstrates its capabilities particularly in the manufacture of bearing rings, where optimum runout characteristics are required for maximum smooth running. Equipped with rotary table and fully automatic tool changer, this vertical grinding machine can master other functions in addition to grinding. Whether turning, milling, drilling, reaming or boring, this system delivers the same impressive results. The vertically arranged spindle swivelling in the range of ± 50° offers plenty of space for machining a wide variety of workpieces. An interchangeable spindle measuring probe guarantees that each individual workpiece is machined in a single clamping with consistently high perfection.

Applications:

- Low-pressure turbine housing

- Bearing ring

Key Industries

- Aerospace

- Automotive

- Defense

- Die & Mould

- Education & Academics

- Machinery & Manufacturing

- Shipbuilding

Brand

Mägerle consistently keeps the brand promise of customized grinding machines that are characterised by precision, reliability and cost effectiveness. Mägerle set the most important milestone in 1980. Its flat and profile grinding machines – now established worldwide – were built with a fully enclosed hydrostatic guide system for the first time. This ground-breaking design principle still distinguishes Mägerle’s cutting-edge technology today, and forms the unique basis for the unsurpassed results in precision, cost effectiveness, reliability and long working life.

Similar Products

Download now