Schleuniger – Automatic Cut and Strip Machines

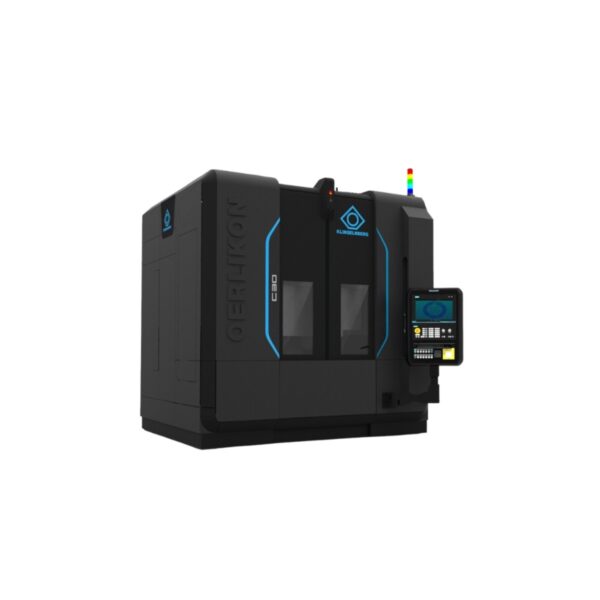

Automatic cut and strip machines designed to process various types of wire and cable applications.

Schleuniger’s high performance automatic cut & strip machines accurately process single conductor wire, multi-conductor cable, shielded cable, coax cable, flat ribbon cable, glass optical fiber (GOF) cable, and plastic optical fiber (POF) cable. Highly versatile and productive equipment with user-friendly operation.

Available Models

Video

Key Industries

Brand

Schleuniger is a global technology group headquartered in Thun (CH) and a leading supplier to the wire processing and testing industry. All wire processing and automation competencies are bundled under the brand name Schleuniger Group in four centers of competence in Europe and one operations hub in Asia.

Schleuniger Group offers wire processing solutions such as, wire cutting, wire stripping, wire testing and cable cutting. With its wholly-owned but independently managed company, DiIT AG, headquartered in Krailling near Munich (DE), the Schleuniger Group is also a leading player in the area of digitalization and industrial Internet of Things (IoT).

Similar Products