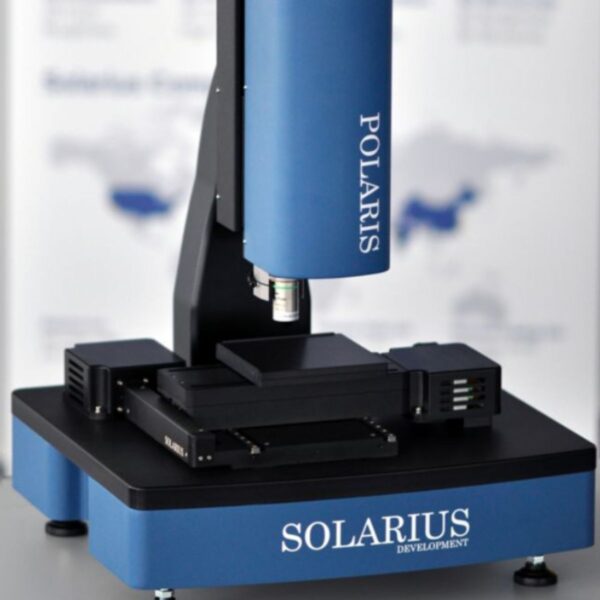

Viscom_Bond Inspection_X7056-II BO

The inspection system X7056-II BO effectively combines optical in-line wire bond control with automatic X-ray inspections. This comprehensive inspection concept enables higher efficiency, optimizes cycle times and thus improves throughput. Where the bottom line is concerned, procurement costs are significantly lower than purchasing two separate inspection systems. The Viscom inspection software is designed for maximum inspection depth and accuracy. The standard library contains inspection patterns for die, ball-wedge, wedge-wedge and security bonds. The inspection scope can be individually extended. During the inspection, high-resolution optical camera technology captures all bond sites and wires. The automatic X-ray inspection then follows seamlessly. Thus, for example, hidden connection sites can also be reliably inspected in one run.

Technical Specifications

| X7056-II BO | ||

| Inspection Scope | Solder paste deposits (stencil printing or dispensing technology, up to pad sizes for 01005 components); sinter paste, adhesives, surface, height, print displacement, smearing, shape, coplanarity, open area analysis, OCR, DMC. | |

| Camera technology | Z-resolution | 0,1 μm |

| Resolution | 12 µm | |

| Field of view | 58 mm x 58 mm (2.2″ x 2.2″) | |

| Inspection speed | Up to 80 cm²/s | |

| System Computer | Processor | Intel®Core™i7 |

| PCB handling | PCB dimensions | 508 mm x 508 mm (20″ x 20″) |

Key Features

- Combined bond AOI and bond AXI

- Maximum inspection depth

- Versatile camera module selection for thick and thin wires

- High-throughput wire bond inspection

- Maintenance-free sealed microfocus X-ray tube

- Can be used as a 3D AXI system or a combined 3D AXI / 3D AOI system

- Ideal for previously sealed circuits with thin wire bonds

- Outstanding solder joint inspection on power semiconductors

- High-precision inspection of single or double-sided electronic assemblies

- Maximum inspection program optimization through integrated verification

- Additional vertical slices for optimum analyses and dependable verification

- High-quality 3D AXI volume calculation with planar CT

Brand

DKSH partnered with Viscom, which was founded in 1984 in Hanover, Germany. Viscom SE has grown into a leading global provider of advanced automatic optical and X-ray inspection systems for electronics production. Viscom offer everything from one source – development, design and sales of our inspection systems, as well as expert software and a comprehensive service package.

Viscom’s inspection systems play a key role in ensuring quality and optimizing processes in industrial electronics manufacturing. Their state-of-the-art solutions are used for fully automated inspections of electronic assemblies, supporting a wide range of industries, including automotive and consumer electronics. Strives for 100% error detection, making its systems vital for customers seeking high precision and reliability in their production processes.

Similar Products