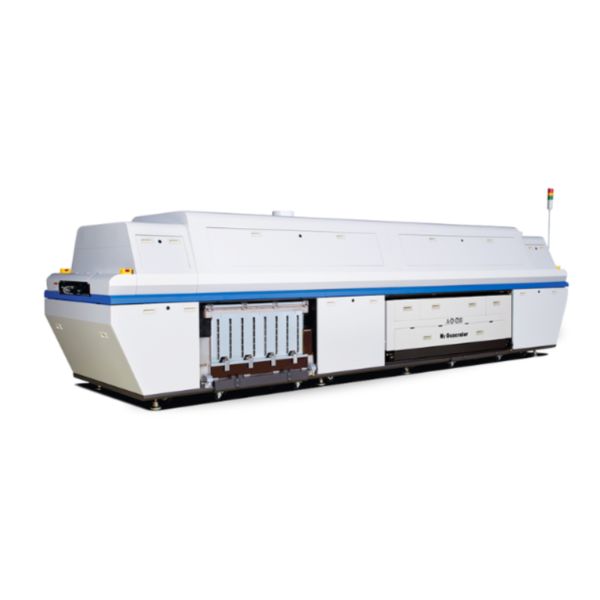

Viscom – Solder Paste Inspection – iS6052-SPI

The iS6052 SPI is Viscom’s cutting-edge solution for precise solder paste inspection in SMD production. With over four decades of expertise behind it, this 3D inline system ensures comprehensive evaluation of key solder features such as volume, height, shape, and more. Advanced sensor technology, including an orthogonal camera and four lateral views, enhances inspection accuracy, while realistic color imaging accelerates verification. The Fast Flow handling system boosts throughput, synchronizing assembly flow seamlessly and minimizing handling times. Equipped with intelligent networking capabilities, the iS6052 SPI offers superior process stability and efficiency for modern SMT lines.

Technical Specifications

| IS6052 SPI | ||

| Inspection Scope | Solder paste deposits (stencil printing or dispensing technology, up to pad sizes for 01005 components); sinter paste, adhesives, surface, height, print displacement, smearing, shape, coplanarity, open area analysis, OCR, DMC. | |

| Camera technology | Z-resolution | 0,1 μm |

| Resolution | 12 µm | |

| Field of view | 58 mm x 58 mm (2.2″ x 2.2″) | |

| Inspection speed | Up to 80 cm²/s | |

| System Computer | Processor | Intel®Core™i7 |

| PCB handling | PCB dimensions | 508 mm x 508 mm (20″ x 20″) |

Key Features

- Proven 3D Camera Technology: One orthogonal camera and four angled-view cameras provide basically shadow-free 3D inspections

- Versatile Application: Specifically designed to meet the needs of most SMD production environments, making it adaptable to a wide range of applications.

- Efficiency: high inspection speed can easily meet demanding cycle time requirements

- Real Time: Effective process control and optimization

- Robust System Design: Ideal system configuration for costs/benefits

Brand

DKSH partnered with Viscom, which was founded in 1984 in Hanover, Germany. Viscom SE has grown into a leading global provider of advanced automatic optical and X-ray inspection systems for electronics production. Viscom offer everything from one source – development, design and sales of our inspection systems, as well as expert software and a comprehensive service package.

Viscom’s inspection systems play a key role in ensuring quality and optimizing processes in industrial electronics manufacturing. Their state-of-the-art solutions are used for fully automated inspections of electronic assemblies, supporting a wide range of industries, including automotive and consumer electronics. Strives for 100% error detection, making its systems vital for customers seeking high precision and reliability in their production processes.

Similar Products