Studer – Internal Cylindrical Grinding Machines

-

MALAYSIA

Robert Puschmann, Managing Director

DKSH Technology Sdn Bhd

B-11-01, The Ascent, Paradigm, No. 1, Jalan SS 7/ 26A, Kelana Jaya

47301 Petaling Jaya, Selangor Darul Ehsan

Malaysia

-

SINGAPORE

Kelvin Low, Senior Manager

DKSH Singapore Pte Ltd

625 Lorong 4 Toa Payoh, #03-00

319519 Singapore

Singapore+65 6274 1222

+65 6273 1503

-

TAIWAN

Weilun Tsao, Managing Director

DKSH Taiwan Ltd.

10F, No. 22, Lane 407, Ti-Ding Blvd., Section 2, NeiHu Technology Park

11493 Taipei City

Taiwan

-

S121_Brochures

-

S141_S151_Brochures

The internal cylindrical grinding machines are designed to solve almost anything you need: Flange parts, spindle shafts, spindle housings, rotor shafts, bushes and much more for the areas of machine tools, drive elements, aerospace and toolmaking.

Whether flange parts or spindles up to 1 300 mm (51.1″) in length, the universal internal cylindrical grinding machines can master any challenge.

Available Models

Technical Specifications

| Height of centres | 102 mm. |

| Workpiece length | 0-230 mm. |

|---|---|

| Workpiece diameter | 0-120 mm. |

| Max. workpiece weight | 50Kg. |

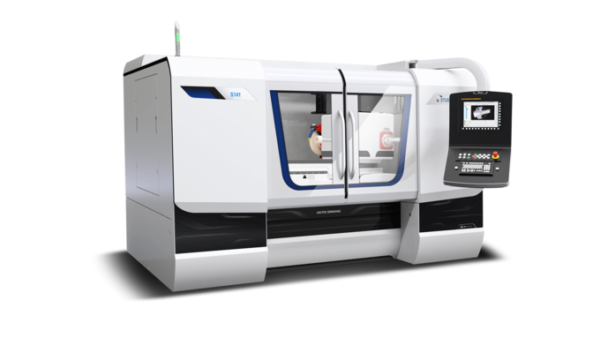

The S110 is a very flexible internal cylindrical grinding machine for machining medium-sized workpieces. The machine has a centre height of 102mm (4″) and a grinding length of max. 120mm (4.7″).

Dimension

| Height of centres | 200 mm. |

| Workpiece length | 0-300 mm. |

|---|---|

| Workpiece diameter | 0-360 mm |

| Max. workpiece weight | 100 Kg. |

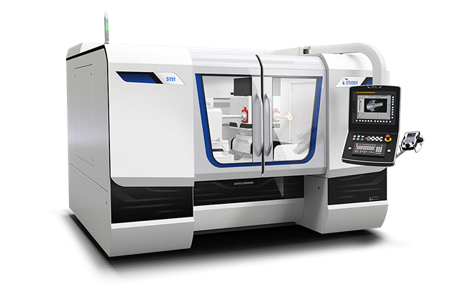

The S121 universal internal cylindrical grinding machine has an exceptional price/performance ratio and is the ideal machine for internal, surface and external grinding of chuck components. It has a host of sophisticated technical features such as the revolutionary StuderGuide® guideway system, high-precision axis drives with linear motors, a swivel-in dressing unit, etc. The S121 is the ideal machine for a wide range of internal grinding applications. Many workpieces are in the areas of machine tools, drive elements, aerospace, die and mold.

Precision is the result of perfect interaction between a large number of different factors. The basis is the Granitan® S103 machine bed with its excellent cushioning and thermal behavior. The modules are ideally suited to each other and produced with the customary STUDER precision. The large distance between the guideways and the very rigidly constructed slides form the basis for the precision and productivity of this machine. All components involved in defining precision are temperature-stabilized.

StuderWIN creates a stable programming environment and contributes to efficient use of the machine. A PC is integrated into the CNC control system. The possibility of fully integrating the in-process gauging and sensor technology for process monitoring as well as contact detection and balancing systems in the control enable standardized programming of the different systems. The drive elements are optimally adapted to the control.

Technical Specifications

- Swing diameter above the table 400 mm

- Max. workpiece length (including clamping device) 300 mm

- Internal grinding length 175 mm

- Maximum workpiece weight 125 kg

- StuderGuide® guide system with linear drive

- Spindle turret with two grinding spindles or one fixed spindle

- C-axis for the workhead enabling form and thread grinding

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

- Very simple operation and programming thanks to StuderWIN

- Short setup and resetting times e.g. with Studer Quick-Set

- Standardized interfaces for loader and peripheral devices

Technical Specifications

| Height of centres | 150 mm. |

| Workpiece length | 0-300mm. |

|---|---|

| Workpiece diameter | 0-300mm. |

| Max. workpiece weight | 100 Kg. |

The S121 is a radius internal cylindrical grinding machine. It is the ideal machine for internal, face and external grinding of chuck components. The maximum swing diameter is 300mm (25.6″) and the maximum workpiece weight is 100kg (220lbs).

Technical Specifications

| Height of centres | 110 mm. |

| Workpiece length | 0-120 mm. |

|---|---|

| Workpiece diameter | 0-70 mm |

| Max. workpiece weight | 3 Kg. |

The S122 is a CNC production internal cylindrical grinding machine for small to medium-sized workpieces in small and large-scale production. The machine has a swing diameter of 220mm (8.6″).

Technical Specifications

| Height of centres | 125 mm. |

| Workpiece length | 0-300 mm. |

|---|---|

| Workpiece diameter | 0-250 mm |

| Max. workpiece weight | 100Kg. |

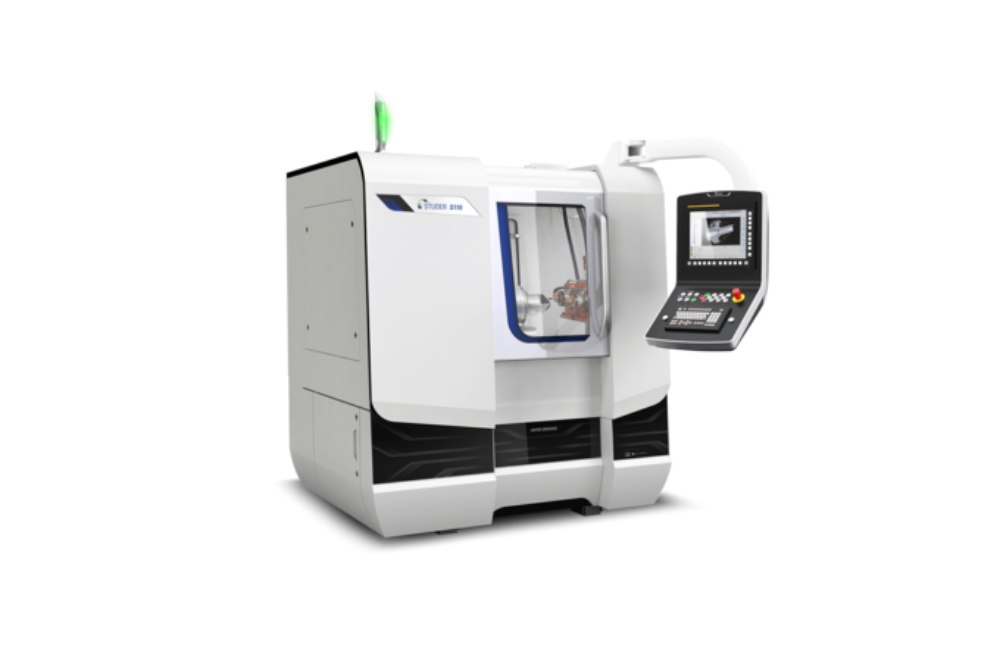

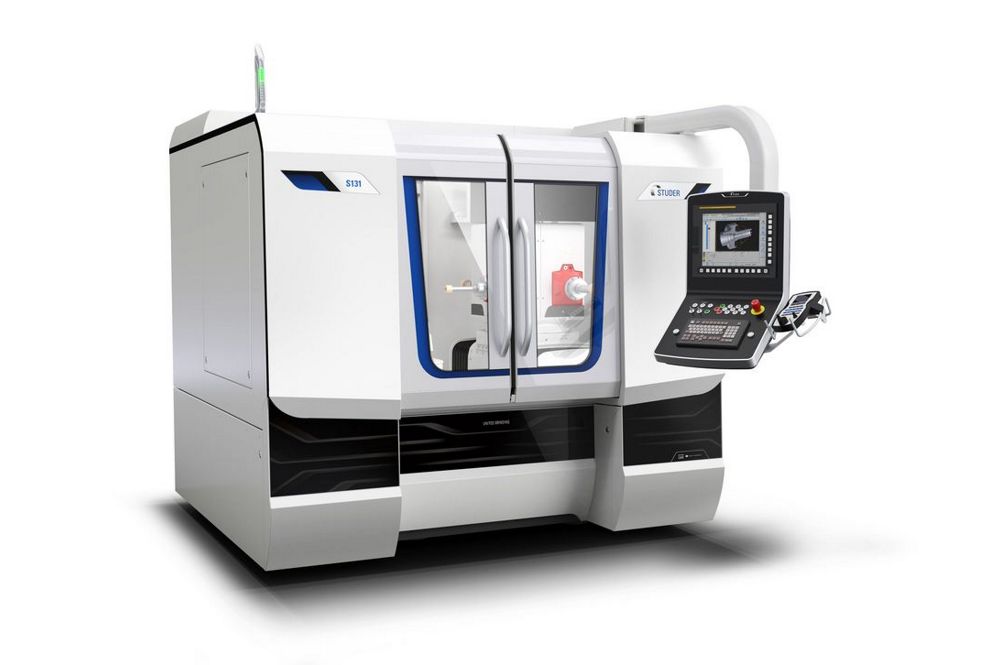

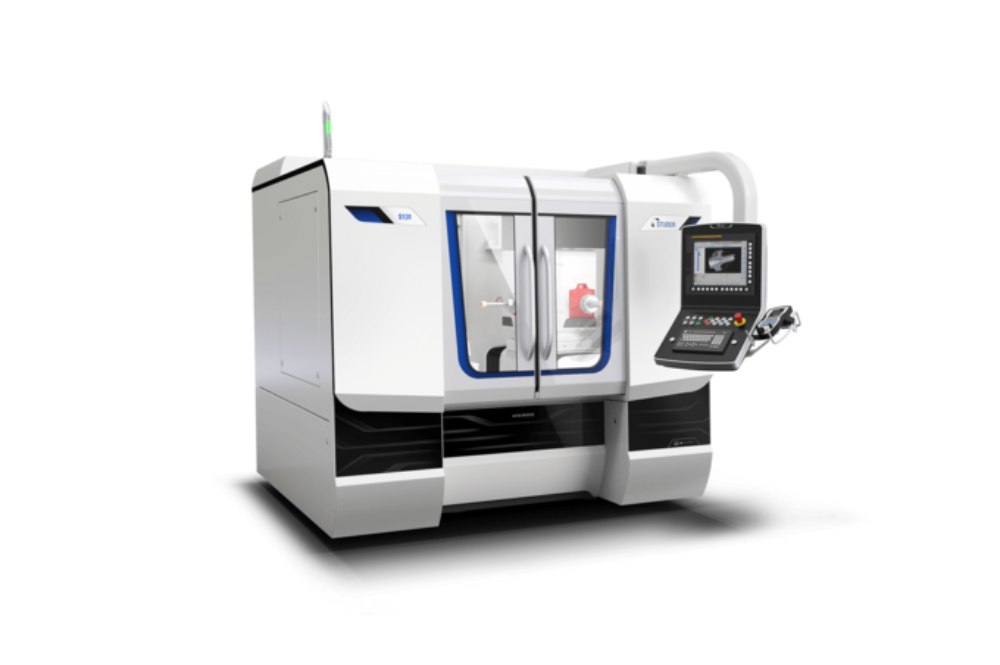

The S131 is a CNC universal internal cylindrical grinding machine of the latest generation. The swing diameter above the workpiece table is 250 mm (9.8″), and the maximum workpiece length (including clamping device) is 300 mm (11.8″).

Technical Specifications

| Height of centres | 150 mm. |

| Workpiece length | 0-300 mm. |

|---|---|

| Workpiece diameter | 0-300 mm. |

| Max. workpiece weight | 1500Kg. |

The S131 is a radius internal cylindrical grinding machine that is especially suitable for grinding complex workpieces from very hard materials The maximum swing diameter is 300mm (11.7″) and the maximum workpiece weight is 100kg (220lbs).

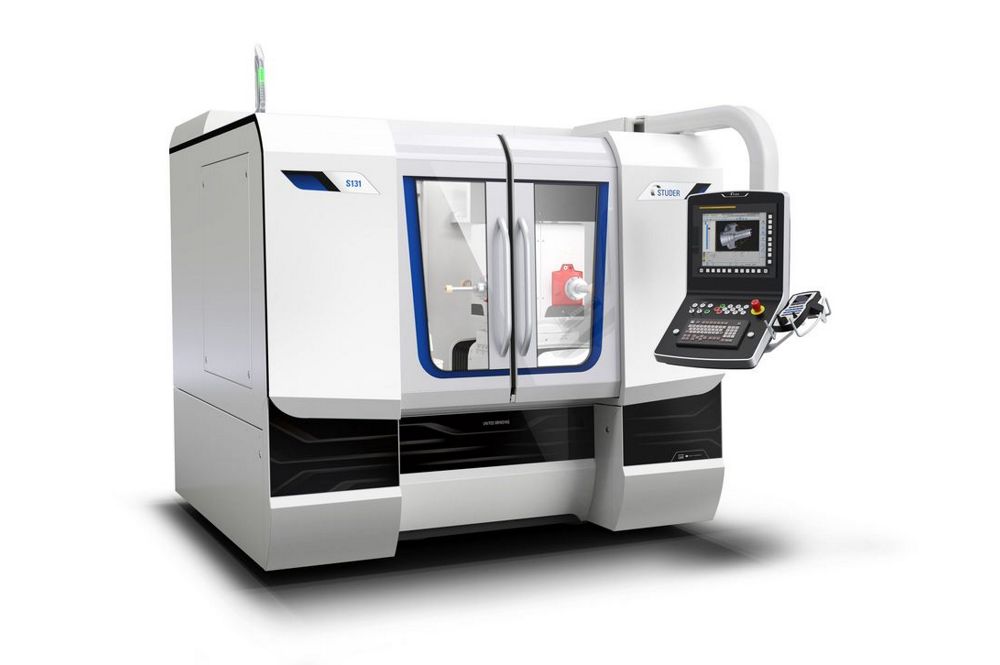

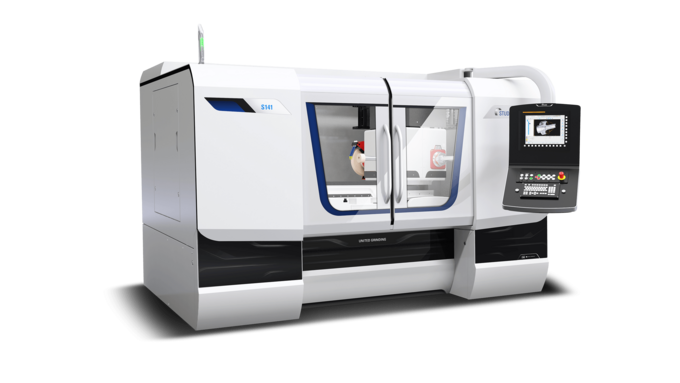

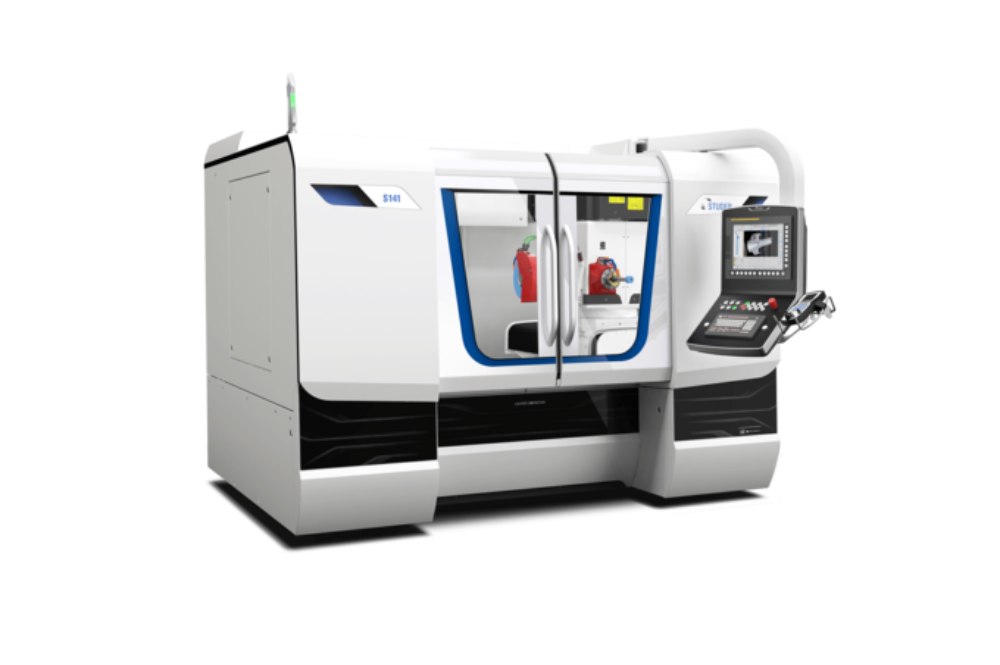

The S141 is a CNC universal internal cylindrical grinding machine of the latest generation. It has a host of sophisticated technical features such as the revolutionary StuderGuide® guide system, high-precision axis drives with linear motors, extremely fast direct drive of the grinding spindle turret, automatic swiveling of the workpiece table etc.

Three sizes are available for workpiece lengths of 300 mm, 700 mm and 1300 mm (11.8″, 27.5″ and 51.1″). For all models the maximum internal grinding length is 250 mm (9.8″) and the external length is 150 mm (5.9″). The S141 is the ideal machine for grinding spindle shafts, spindle housings, rotor shafts, axes or flange parts. Many workpieces are in the areas of machine tools, drive elements, aerospace and toolmaking.

Precision is the result of perfect interaction between a large number of different factors. The basis of the S141 is the machine bed comprising Granitan® S103 with its excellent dampening and favorable thermal behavior. The modules are ideally suited to each other and produced with the customary STUDER precision. The large distance between the guideways and the very rigidly constructed slides form the basis for the precision and productivity of this machine. All components involved in defining precision are temperature-stabilized.

StuderWIN/StuderSIM creates a stable programming environment and contributes to efficient use of the machine. A PC is integrated into the CNC control system. The possibility of fully integrating the in-process gauging and sensor technology for process monitoring as well as contact detection and automatic balancing systems in the control enable standardized programming of the different systems. The drive elements are optimally adapted to the control.

Technical Specifications

- Swing diameter above the table 400 mm (15.7″)

- Max. workpiece length 300 / 700 / 1300 mm (11.8″ / 27.5″ / 51.1″)

- Internal grinding length 250 mm (9.8″)

- Maximum workpiece weight 250 kg (550 lbs)

- StuderGuide® guide system with linear motors

- Grinding spindle turret with up to four grinding spindles

- Automatically swiveling workpiece table

- C-axis for the workhead for form and thread grinding

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

- Very simple operation and programming thanks to StuderWIN or StuderSIM

- Short setup and resetting times e.g. with STUDER Quick-Set

- Standardized interfaces for loader and peripheral devices

Technical Specifications

| Height of centres | 200 mm. |

| Workpiece length | 0-300 mm. |

|---|---|

| Workpiece diameter | 0-400 mm. |

| Max. workpiece weight | 100Kg. |

The S141 is a radius internal cylindrical grinding machine that is especially suitable for grinding complex workpieces from very hard materials The maximum swing diameter is 400mm (15.7″) and the maximum workpiece weight is 100kg (220lbs).

Dimension

| Height of centres | 275 mm. |

| Workpiece length | 0-700/1300 mm. |

|---|---|

| Workpiece diameter | 0-550 mm |

| Max. workpiece weight | 250 Kg. |

The S151 is a CNC universal internal cylindrical grinding machine of the latest generation. It has a host of sophisticated technical features such as the revolutionary StuderGuide® guide system, high-precision axis drives with linear motors, extremely fast direct drive of the grinding spindle turret, automatic swiveling of the workpiece table etc.

Two sizes are available for workpiece lengths 700 mm and 1300 mm (27.5″ and 51.1″). For both models the maximum internal grinding length is 390 mm (15.3″) and the external length is 150 mm (5.9″). The S151 is the ideal machine for grinding spindle shafts, spindle housings, rotor shafts, axes or flange parts. Many workpieces are in the areas of machine tools, drive elements, aerospace and toolmaking.

Precision is the result of perfect interaction between a large number of different factors. The basis of the S151 is the machine bed comprising Granitan® S103 with its excellent dampening and favorable thermal behavior. The modules are ideally suited to each other and produced with the customary STUDER precision. The large distance between the guideways and the very rigidly constructed slides form the basis for the precision and productivity of this machine. All components involved in defining precision are temperature-stabilized.

StuderWIN/StuderSIM creates a stable programming environment and contributes to efficient use of the machine. A PC is integrated into the CNC control system. The possibility of fully integrating the in-process gauging and sensor technology for process monitoring as well as contact detection and automatic balancing systems in the control enable standardized programming of the different systems. The drive elements are optimally adapted to the control.

Technical Specifications

- Swing diameter above the table 550 mm (21.7″)

- Max. workpiece length 700 / 1300 mm (27.5″ / 51.1″)

- Internal grinding length 390 mm (15.3″)

- Maximum workpiece weight 250 kg (550 lbs)

- StuderGuide® guide system with linear motors

- Grinding spindle turret with up to four grinding spindles

- Automatically swiveling workpiece table

- C-axis for the workhead for form and thread grinding

- Full enclosure with two sliding doors

- Granitan® S103 mineral casting machine base

- Very simple operation and programming thanks to StuderWIN or StuderSIM

- Short setup and resetting times e.g. with STUDER Quick-Set

- Standardized interfaces for loader and peripheral devices

S131: Gearbox Shift Wheel

S151 Product Intro

Key Industries

- Aerospace

- Automotive

- Defense

- Die & Mould

- Education & Academics

- Electronics

- Machinery & Manufacturing

- Medical

- Mining & Minerals

- Oil & Gas

- Semiconductor, Solar & Electronics

- Shipbuilding

Brand

STUDER has been writing grinding history since 1912. STUDER has developed from a small enterprise into an internationally active company with around 800 staff. Fritz Studer AG owes its position in the market to the experience gained from building more than 24,000 systems. Its former pioneering spirit is also reflected in its present-day products, and is impressively demonstrated by the quality and quantity of its innovations.